The 8F35 is an 8-speed front-wheel-drive unit from Ford in light-duty applications. Ford Edge and the Transit Connect equipped with the 2.0L GTDI engine are just two examples. This unit is also another example of the General Motors/Ford Motor Company collaborations we’ve seen in the past. Think about the front-wheel-drive six speeds. The GM version is the 9T50, a 9-speed unit (refer to Fun with Transmissions July 2019 for more on that unit).

This edition will take a closer look at the valve body and the solenoids inside the 8F35. We will also look inside the Selectable One-Way Clutch (SOWC) assembly and the cooling system.

UNIT VARIANTS

UNIT VARIANTS

The 8F35 has two different valve bodies; one has the park-by-wire the other has a park-by-cable. The park-by-wire valve body has no manual valve! Instead, it uses an added park lock solenoid to allow the system to remain out of park when the engine is running (figure 1)—the solenoid de-energizes when the engine is off, allowing the park pawl to engage in park. Manually selecting park de-energizes the solenoid as well. Referring to figure 1, we see it has a park lock valve, not a manual valve. The transmission hydraulic controls are modified using the park rod, which unlocks and locks the parking pawl from the carrier. The park-by-wire system has a gear select module (GSM) which includes a rotary knob and hall effect sensors to identify the gear selected.  The park-by-cable valve body has a manual valve. The cable from the shifter operates the manual valve inside the unit. It also moves the park pawl in & out of park. Once the unit is out of park, the computer commands the solenoids to apply the clutches for the commanded gear.

The park-by-cable valve body has a manual valve. The cable from the shifter operates the manual valve inside the unit. It also moves the park pawl in & out of park. Once the unit is out of park, the computer commands the solenoids to apply the clutches for the commanded gear.

SPEAKING OF SOLENOIDS

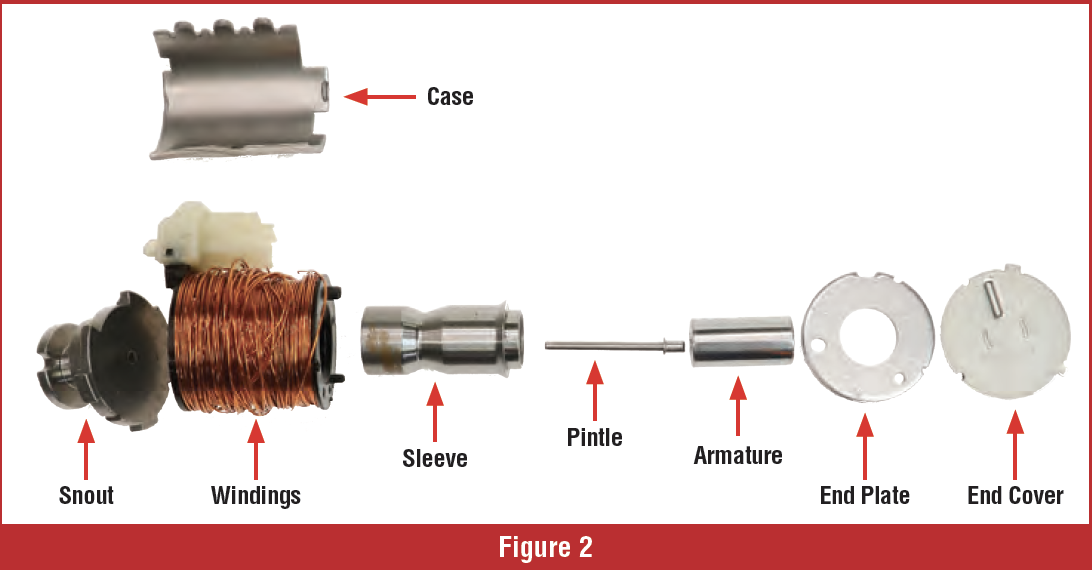

In past articles, I introduced Casting Integrated Direct Acting Solenoids (CIDAS) and how they work directly/mechanically on the valves to apply the clutches for the desired gear. Let’s take a closer look at these mechanical marvels.

One of the many cool parts of my job is looking inside parts of transmissions that the transmission rebuilder/technician typically doesn’t have the time to make the “discovery.” We, as mechanics, are a curious bunch. Taking things apart and putting them back together can be the easy part of rebuilding for us. Those thoughts like the” I wonder what’s inside that solenoid or black box that we are putting into the unit” mentality keep us coming back. This time, I had the opportunity to take out the cutting wheel and ‘disassemble’ the housing of the CIDAS solenoid.

One of the many cool parts of my job is looking inside parts of transmissions that the transmission rebuilder/technician typically doesn’t have the time to make the “discovery.” We, as mechanics, are a curious bunch. Taking things apart and putting them back together can be the easy part of rebuilding for us. Those thoughts like the” I wonder what’s inside that solenoid or black box that we are putting into the unit” mentality keep us coming back. This time, I had the opportunity to take out the cutting wheel and ‘disassemble’ the housing of the CIDAS solenoid.

Figure two shows the layout of the parts inside this direct-acting solenoid. As I was inspecting the working parts of the solenoid, I noticed a fabric sleeve inside the metallic sleeve that lives inside the windings (figure 3). This small sleeve feels like plastic and is slightly larger than a dime (figure 4). Because this is a mechanical solenoid, there is no fluid flushing thru the solenoid, so this sleeve is a barrier between the metallic sleeve and the armature. With a digital microscope, I looked closer at the fabric and noticed that the dark lines in the material were, in fact, carbon fibers (figure 5).

Carbon fibers have several advantages: high stiffness, high tensile strength, high strength to weight ratio, high chemical resistance, high-temperature tolerance, and low thermal expansion. These qualities make for a perfect material for these solenoids.

Carbon fibers have several advantages: high stiffness, high tensile strength, high strength to weight ratio, high chemical resistance, high-temperature tolerance, and low thermal expansion. These qualities make for a perfect material for these solenoids.

SELECTABLE ONE-WAY CLUTCH (SOWC)

One-way clutches, sprags, roller clutch, overrun clutch, mechanical diode, no matter what name they go by, these devices will allow an internal transmission part, such as a planetary gear set, to rotate freely in one direction and lock up in the other direction. Of course, these parts have also been around since automatic transmissions were invented.

In the 8-speed application, the SOWC takes the place of the low-reverse clutch assembly, eliminating the following components:

In the 8-speed application, the SOWC takes the place of the low-reverse clutch assembly, eliminating the following components:

- Low-reverse clutch apply piston

- Low-reverse return spring and snap ring

- Friction plates

- Steel plates

- Pressure plate and retaining snap ring

It’s all about fuel economy when we get rid of extra components and weight.

It’s all about fuel economy when we get rid of extra components and weight.

You can go to the Virtual Training Solutions section of the ATRA Tech website and check out the videos that discuss the disassembly and assembly of the SOWC (figure 6). The other added benefit the SOWC provides is engine braking in 1st gear when the SOWC is in the locked position. When the D solenoid is commanded on, this deploys a strut preventing the planetary components from rotating forward, allowing engine braking.

COOLING SYSTEM

Sometimes I like to reminisce about the good old days. Back in the day, steel lines ran to a fluid-to-fluid cooler at the bottom of the radiator. Fixing a rub-through leak involved a piece of copper tubing and a couple of brass compression fittings. I know some old-school guys think I am getting fancy instead of using a cooler hose and a couple of hose clamps!

Sometimes I like to reminisce about the good old days. Back in the day, steel lines ran to a fluid-to-fluid cooler at the bottom of the radiator. Fixing a rub-through leak involved a piece of copper tubing and a couple of brass compression fittings. I know some old-school guys think I am getting fancy instead of using a cooler hose and a couple of hose clamps!

Now, let’s fast forward to the 8F35 and check out all the things that are now a part of today’s cooling systems. First, it’s essential to understand that transmission fluid flows best at a specific temperature; when it’s below that temperature, it causes too much drag. As we all know, too much drag means too much fuel consumption. With gas prices the way they are, we need all the fuel mileage we can get!

The 8F35 system is equipped with a transmission fluid warmer, a cooler bypass valve, and a transmission fluid cooler (figure 7). The transmission fluid warmer is a coolant-to-transmission fluid heat exchanger mounted on the transmission. The transmission fluid cooler is a transmission fluid-to-air cooler mounted in front of the A/C condenser. The cooler bypass valve is mounted on the transmission. When the transmission fluid is below the normal operating temperature, transmission fluid travels from the transmission to the transmission fluid warmer, to the cooler bypass valve, and back to the transmission. When the transmission fluid is at or above normal operating temperature, the cooler coolant control valve closes, stopping coolant flow to the transmission fluid warmer. The cooler bypass valve opens, allowing transmission fluid to travel from the transmission through the cooler and back to the transmission. The transmission fluid cooler transfers heat from the transmission fluid to the ambient air.

The 8F35 system is equipped with a transmission fluid warmer, a cooler bypass valve, and a transmission fluid cooler (figure 7). The transmission fluid warmer is a coolant-to-transmission fluid heat exchanger mounted on the transmission. The transmission fluid cooler is a transmission fluid-to-air cooler mounted in front of the A/C condenser. The cooler bypass valve is mounted on the transmission. When the transmission fluid is below the normal operating temperature, transmission fluid travels from the transmission to the transmission fluid warmer, to the cooler bypass valve, and back to the transmission. When the transmission fluid is at or above normal operating temperature, the cooler coolant control valve closes, stopping coolant flow to the transmission fluid warmer. The cooler bypass valve opens, allowing transmission fluid to travel from the transmission through the cooler and back to the transmission. The transmission fluid cooler transfers heat from the transmission fluid to the ambient air.

Since an actuator controls coolant flow to the fluid warmer, the cooling system has two trouble codes the PCM can generate; A P2681 Engine Coolant Bypass Valve “A” Circuit Open and a P2683 Engine Coolant Bypass Valve “A” Control Circuit High.

Since an actuator controls coolant flow to the fluid warmer, the cooling system has two trouble codes the PCM can generate; A P2681 Engine Coolant Bypass Valve “A” Circuit Open and a P2683 Engine Coolant Bypass Valve “A” Control Circuit High.

SPECIAL TOOLS

Earlier, we talked about the Selectable One-Way Clutch (SOWC). On the other side of the SOWC housing is the A clutch assembly. The A clutch is applied in 1st thru 5th gears and holds the output sun gear shell from turning (figure 8).

The tricky thing about the A clutch assembly is installing the A clutch return spring. Removing the retaining snap ring is easy; get a screwdriver in there, and the thing pops right out. Now installing the snap ring is a whole different story. In the past, we have been able to figure out ways to compress these pesky Belleville return springs and get the snap ring installed. The issue with this part is that it’s so thin that it’s challenging, if not impossible, to get something in there and compress the spring to get the snap ring into the groove.

A specialty tool comes into play to make this job easy! Once the return spring and the snap ring are in position inside the housing, special tool #307- 767 is used to install the snap ring (figure 9). When the tool is installed and used in a press, it does two things simultaneously; it compresses the return spring and pushes the snap ring down. Then, as we continue to press on the tool, an audible “snap” can be heard. This “snap” is the retaining snap ring seating into the groove (figure 10).

A specialty tool comes into play to make this job easy! Once the return spring and the snap ring are in position inside the housing, special tool #307- 767 is used to install the snap ring (figure 9). When the tool is installed and used in a press, it does two things simultaneously; it compresses the return spring and pushes the snap ring down. Then, as we continue to press on the tool, an audible “snap” can be heard. This “snap” is the retaining snap ring seating into the groove (figure 10).

Now that we have taken a closer look at the CIDAS solenoids, the SOWC, the cooling system, and the special tools on the A clutch return spring installation, it’s an excellent time to cruise over to the ATRA Virtual Training Solutions (VTS) web site. Once you are there, you can access seventeen 8F35 training videos to guide you through the entire unit. Always remember: when we learn more about what we are working on, it’s easier to have Fun with Transmissions!