Over the past several months, we’ve covered a lot of information aimed at the diagnostician, particularly things to check when a vehicle first comes in with a transmission-related complaint. Some items, like battery voltage and condition, are easily overlooked. In the April edition, we covered this and the effects of other often-overlooked items like mismatched tires and worn spark plugs. Transmission complaints from items like these are generally seen on high-milage vehicles with a poor maintenance schedule. That is, the vehicle is long out of the factory warranty, and “Hey, the car starts, so the battery is fine.” Or, the engine runs fine, so who cares that the vehicle has 143,278 miles and still has the original spark plugs. These, as well as using a spare tire of a different size or the wrong brake light bulbs, fit into the category of a poorly-maintained vehicle and customer-caused issues. By asking the customer better questions, you can understand their maintenance habits and scrutinize items you might overlook.

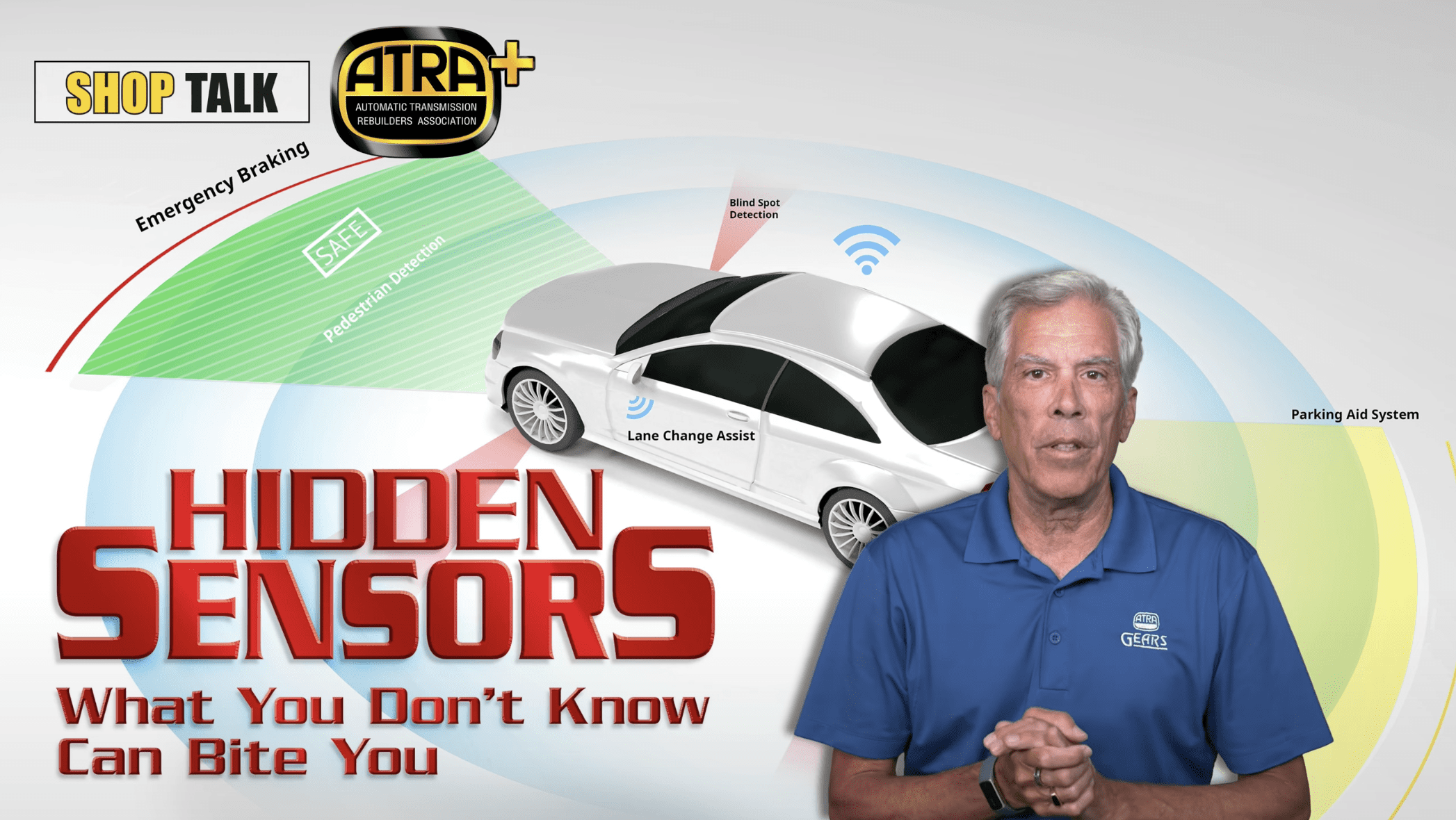

In this article, we’ll cover a few sensors that may fail yet not set a code. You might consider them hidden sensors, since the computer accepts their bad signal as normal and alter the transmission shift strategy accordingly. This is by no means a complete list; rather, it’s intended to expand your diagnostic range.

Add ID a little above video:

Keep in mind as we go through these sensors that, increasingly, the computer tries to emulate what a driver might do while driving a standard transmission. Consider how you might drive while going up or down a grade or turning a corner. You might stay in a lower gear longer under these conditions. By the way, some vehicles not only downshift the transmission while going down a grade, but they can also apply the brakes with no brake input by the driver. Let’s get started.

BRAKE PEDAL POSITION (BPP) SENSOR

Let’s start with the BPP sensor. Steve Garrett introduced this sensor in his article on page 28. The computer uses this sensor to recognize that a vehicle is going down a grade. If a vehicle speed increases and the computer sees no throttle input and then sees the driver pressing harder on the brake, it knows how steep a grade is or that the vehicle is heavily loaded. In any event, the computer will respond by downshifting the transmission for grade retard. As Steve pointed out, it can also reduce engine output. Also included in the article are additional complaints you might find and diagnostic procedures.

STEERING ANGLE SENSOR (SAS)

This is a tricky subject. It’s far more vast than you might first consider. The bottom line is that the Body Control Module (BCM) wants to know if the car is going straight or around a turn – even a slight turn. It communicates this with other modules and can result in a modified shift strategy. It may or may not disable the Electronic Stability Program and turn on the ESP light, so you might be unaware of this problem. It could be that the customer had some front-end work done, and now the steering wheel is off. After any front-end work, including an alignment, you’re supposed to re-calibrate the SAS. Perhaps that wasn’t done during the front-end work. Here’s an example of where asking the customer for prior repairs comes in. This also questions whether disrupting the front suspension during the R&R of a FWD transmission might affect this too.

And while we’re on the topic of the computer thinking the car is turning, don’t forget to check the tires. Make sure they’re matched, not only in size but manufacturer, and that they’re inflated properly.

KNOCK SENSOR

The knock sensor is a piezoelectric device that listens to engine sounds. If it senses cylinder pre-detonation (which could be due to nothing more than bad gas), it’ll cause the computer to retard the ignition and alter the fuel mixture to resolve the problem. It may also limit a shift into overdrive or eliminate it entirely. A failed knock sensor can cause some or all of these conditions while not setting a code.

For this, you’ll want to ask the customer how long the problem existed. Ask them about changes in fuel purchases and whether they recently went to a different station. And you certainly want to verify whether you can electronically shift the transmission through all ranges. This is another tricky one and has fooled even the most seasoned technicians.

SHIFT MODE SENSORS

SHIFT MODE SENSORS

Shift mode sensors like traction control and tow/haul switches allow the driver to modify shift timing and feel for certain conditions, like towing a trailer or driving on snow and ice. In the case of a tow/haul switch, the computer delays the shifts and raises transmission line pressure. The traction control switch generally forces the transmission to start from a stop in 2nd gear. Since using these switches is perfectly normal, the computer won’t flag them if they’re stuck or damaged. Check them during your initial road test and make sure the transmission behaves normally based on the switch position. And check the switch location to see if it’s located in a place where the customer might accidentally engage the switch. Figure 1 shows the “Trac” switch right below the shifter. It’s a great place to put a purse.

O2 SENSOR

The computer uses the O2 sensor to manage fuel delivery. Anytime something affects engine performance, it can affect transmission operation. Oddly, this is both narrow and broad at the same time. That is, the O2 sensor is a simple device, but you can’t necessarily forecast in what way it may affect the transmission when it fails. The best way to avoid O2 sensor modalities is to better understand and diagnose the device. For more on this topic, read Scott Shotton’s article in the 2018 issue of GEARS Magazine. Gears Magazine – Oxygen Sensors, Part I

These are some of the more common sensor failures you’ll likely encounter. They may not set a code, but they can upset transmission performance and generate customer complaints. Some of the more sophisticated systems include G-Force sensors and even Radar, all designed to understand what the driver is doing and examine the surroundings.

Since the advent of automatic transmissions, engineers have tried to duplicate the actions of a driver of a standard transmission. And like a driver not paying attention to the road, an automatic transmission can act up periodically, too. Look for more diagnostic information here at , and look for the ATRA+ logo.