Change is one word that folks in this industry either love or hate. The GM 8-speeds are making their mark in our industry as many shops are seeing more and more of them come into their facilities for repair. While many had hoped that the 10-speed would replace the 8-speed, it appears that the 8-speeds may be here for the duration. The unit has a pretty good track record when it comes to durability, but that cannot be said when it comes to the quirks the units exhibit. In an attempt to address some shift-related concerns, GM has spent a ton of money and time updating the units over the last several years.

Starting in the 2023/2024 model years, you will see the advent of Generation II for the 8-speed applications. With the advent of Gen II, a new RPO code was introduced, “MFC,” with the new “8L80” designation and “N8R” for the Gen II 8L45. The GEN II 8L80/8L45 applications have a couple of quirks that, as a shop, you need to be aware of, or you may attempt to fix something that is not broken.

One of the issues we have had with the 8L applications since early on was due to a hard part update designed to address converter drain back issues. After the update was implemented, another issue arose, a flare on the 1st shift after the vehicle was left sitting for an extended period. After the clutch cycled one time, the shift issue was no longer present.

This was due to air migrating into the clutch apply circuit while the vehicle was not operating. When the clutch applied, the air had to be forced from the drum, which slowed the clutch’s application, resulting in the complaint. As I told you in the ATRA seminars, there is very little you can do to address the issue. GM released some updated calibrations, but those never fully addressed the issue.

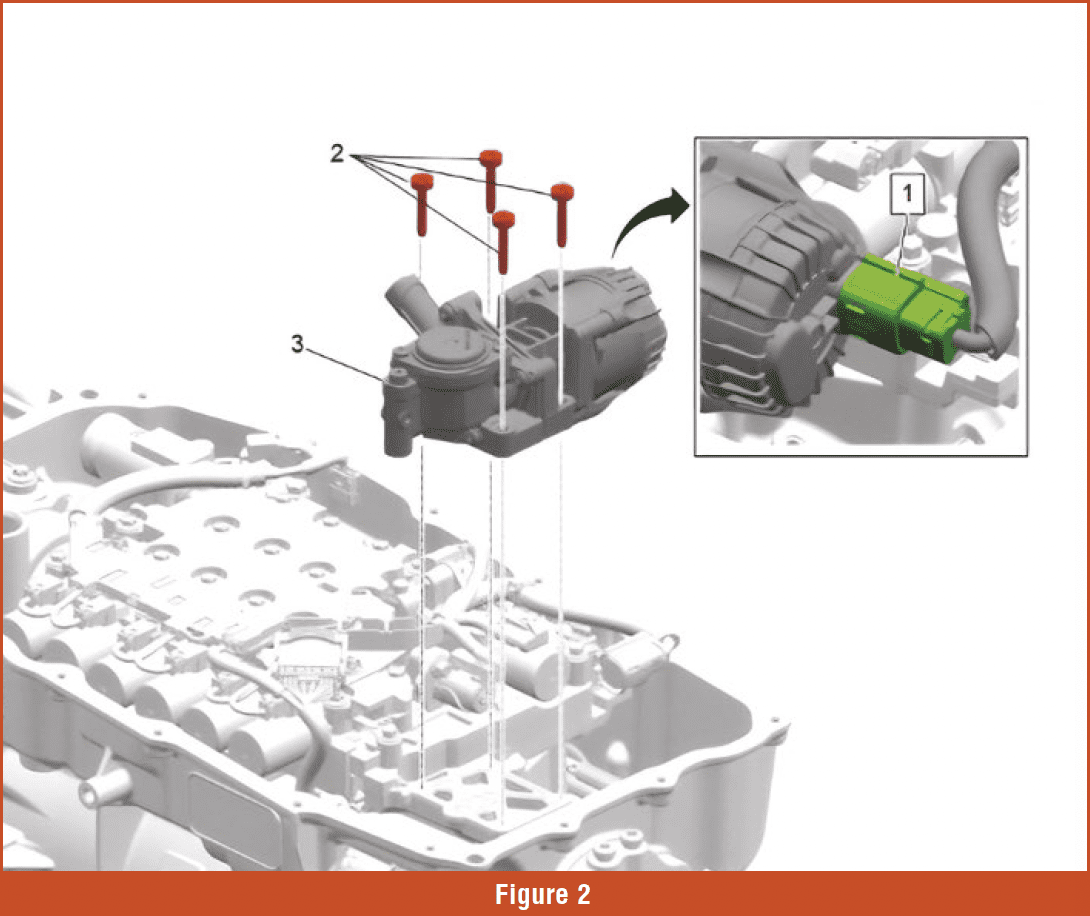

The GEN II units are equipped with a new electric/hydraulic pump and pressure sensor, which replaces the start/stop accumulator and solenoid used in the other applications. To trigger the pump, the Body Control Module (BCM) sends a signal to the Transmission Control Module (TCM) regarding the driver’s door switch position. The GEN II applications run the start/stop auxiliary pump and cycle the valve body solenoids when you open the door. This action is designed to purge the air from the system before the customer starts the vehicle. What this means from a shop standpoint is that the customer may now comment regarding a buzzing noise coming from the transmission area when he/she opens the door. Here is how it works:

The GEN II units are equipped with a new electric/hydraulic pump and pressure sensor, which replaces the start/stop accumulator and solenoid used in the other applications. To trigger the pump, the Body Control Module (BCM) sends a signal to the Transmission Control Module (TCM) regarding the driver’s door switch position. The GEN II applications run the start/stop auxiliary pump and cycle the valve body solenoids when you open the door. This action is designed to purge the air from the system before the customer starts the vehicle. What this means from a shop standpoint is that the customer may now comment regarding a buzzing noise coming from the transmission area when he/she opens the door. Here is how it works:

- When the door is opened, the customer will hear a whine-type noise and a clicking sound which will last about 10 seconds.

- After 10 seconds, the sounds will stop. At that point, there will be a couple of seconds pause, at which point the whine and clicking sounds will resume for another 10 seconds.

- What the system is doing is applying and releasing the clutches in an attempt to purge any air trapped in the system.

- Of course, if the vehicle is parked in a garage, the sound will be even more apparent.

- In addition, since this electro/ hydraulic pump is replacing the start/ stop accumulator and solenoid, you may hear the pump operating when the vehicle comes to a stop, and the engine is shut off (Figures 1 & 2).

Another issue that your customers may comment on a harsh garage shift on the first engagement after the vehicle has been left sitting for a length of time. This issue applies to multiple 6/8/9 and 10-speed units. This, too, is normal, even though my wife would love to have it fixed. It is known as “catalytic converter light off” (CLO).

Another issue that your customers may comment on a harsh garage shift on the first engagement after the vehicle has been left sitting for a length of time. This issue applies to multiple 6/8/9 and 10-speed units. This, too, is normal, even though my wife would love to have it fixed. It is known as “catalytic converter light off” (CLO).

If the customer gets into the vehicle and immediately places the vehicle into gear upon starting the engine, the engagement will be harsh. This issue is even present in the GEN 1 applications. In addition, it is present on many other transmission families, so you likely have already received complaints from customers.

The ECM elevates the engine speed for about 90 seconds after starting in an attempt to raise the temperature of the catalytic converter so the CAT can function sooner, reducing emissions. When the CLO program is active, the ECM will:

- Elevate idle speed

- Retard spark timing

- Add additional injector pulses

- This program will be active if the engine coolant temperature is below 158° F (70° C) during engine starting and will remain active for 25 to 90 seconds.

Like any vehicle, if the engine speed is elevated, the garage shift may appear harsh to the customer. The issue is considered normal in this case, so do not try to fix it. If the customer waits until the engine speed drops to a normal idle speed, the engagement will be smooth once again.