When you see the familiar black and gold TransTec® bag, you know you can trust that you’ll find the highest quality components available inside. What you may not realize is that TransTec® is brought to you by the world’s largest OEM automotive sealing parts manufacturer. Products and solutions from Freudenberg-NOK Sealing Technologies are usually invisible, but always indispensable. With market trends being driven by both legislative and environmental forces, the company’s product portfolio and advanced manufacturing processes are helping automotive manufacturers meet demands to improve fuel economy as the industry adopts 9and 10-speed transmissions.

From increasing number of speeds (6-7-8-9-10-14) for improved fuel efficiency, that leads to lower CO2 emissions, to the increased use of start/stop technology, Freudenberg-NOK is at the forefront of developing technologies to support original equipment manufacturers. The company currently has 30 seals on one major manufacturer’s new 10-speed transmission that debuted at the 2016 North American International Auto Show.

As the industry continues to evolve, Freudenberg-NOK has taken a leadership role in helping its customers resolve the complex issues associated with today’s global market demands. The drive to improve fuel economy and lower emissions continues to impact every aspect of vehicle development. The company is proud to collaborate with customers on the development of components and systems that will help them successfully meet their development objectives.

Eight North American manufacturing plants including those in Findlay, Ohio, Manchester, Northfield and Bristol N.H., Morristown, IN, LaGrange and Cleveland Ga., and Querétaro, Mexico are supplying components to the new transmission systems. The company has been working on development of all-new components for, in some cases, more than four years. Freudenberg-NOK engineers have worked side-by-side with engineers at customer facilities to help determine the design, material makeup and manufacturing processes used to develop seals and gaskets that support the new transmissions.

New High Temperature and Lightweight Materials

The new 9- and 10-speed transmission programs being pursued by OEM manufacturers have enabled Freudenberg-NOK to introduce products made of new materials. One new pan gasket being manufactured by the company, for example, is being molded from Freudenberg-NOK’s best-in-class fluoroelastomer (FKM). This mate rial offers customers significant temperature benefits in transmissions that are smaller, more powerful and run at higher temperatures.

In addition, the adoption of 9and 10-speed transmissions has pushed Freudenberg-NOK to look at innovative new ways it can help customers achieve fuel savings through light-weighting of individual components. The company is now molding a two part cover module formerly made of metal from a high performance thermoplastic that saves up to 50 percent of the part weight to help with fuel efficiency and emission reductions.

New Industrial Processes

The push to perfect quality in every part of a new vehicle encouraged Freudenberg-NOK to adopt new, precision-driven manufacturing processes.

In cooperation with its major OEM customers, for example, the company’s Cleveland Transmission and Driveline Lead Center (Cleveland associates photo) has developed a new automated visual inspection and laser etching system for parts. The system relies upon active and dynamic statistical process control at the point of manufacturing. Seals are automatically examined and component-specific data is collected and retained, making product analysis and traceability possible long after the part has been in the field. This innovative system provides higher value while eliminating the risk that nonconforming components will reach the end customer.

Additionally, 10-speed transmission component development has resulted in new manufacturing technology being implemented at the company’s LaGrange facility. There, a new lathe cut process for larger-scale O-rings incorporates a variety of innovations including new tools that eliminate engineered waste and improve the quality of finished components.

OE – Aftermarket Connection

But what does all of this mean for the aftermarket? Simple. It means that the company that brings you TransTec® brand automatic transmission overhaul kits is a global leader in proactively developing OEM solutions and bringing those technologies to the aftermarket. Every day of every week we are perfecting both designs and materials for the aftermarket by leveraging our OE manufacturing. This gives us a unique and distinct position as the only aftermarket kit supplier to also supply to OEM manufacturers.

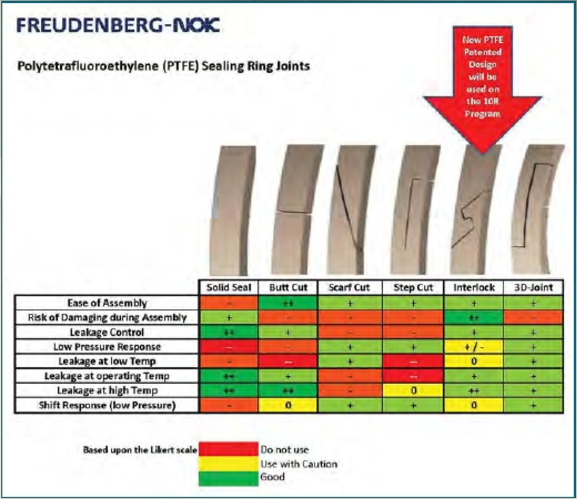

For instance, the company’s Findlay, OH plant produces 185 million polytetrafluoroethylene (PTFE) sealing rings and related products annually and is not only a benchmark for lean manufacturing, but it also controls the entire supply chain. From engineering design, to development and manufacturing of raw materials, to molding the final product. The company’s engineers are design responsible, meaning they determine joint design and material composition depending upon where the ring in used as well as the performance requirements within each particular application.  Freudenberg-NOK engineers draw on their collective experience with global applications and the company’s technology-leading manufacturing capabilities to create sealing components that exceed typical OEM standards. Technological advances learned from past research lead to enhancements for future development.

Freudenberg-NOK engineers draw on their collective experience with global applications and the company’s technology-leading manufacturing capabilities to create sealing components that exceed typical OEM standards. Technological advances learned from past research lead to enhancements for future development.

Building on over three decades of experience with PTFE transmission seals, the team at Freudenberg-NOK began their journey working on designs for 4-speed automatic transmissions for GM and Ford. Following that, the company designed and launched all PTFE rings for GM and Ford 6-speeds and in the process developed a proprietary Quantum® PTFE formulation that was introduced in 1999. This new material essentially doubled the seal’s PV limit (e.g. the pressure and velocity at which the seal can function). Today the company’s engineers are designing, testing and launching seals for 9and 10-speed units while simultaneously developing products for future transmissions with global OEMs. And currently, Freudenberg-NOK maintains approximately 90% of all transmission PTFE sealing rings for the Detroit 3 OEMs.

And it doesn’t stop there. The company has continued to develop new products and processes to support the unique requirements of automotive applications and today is the only supplier with a full portfolio of materials. In fact, the industry recognizes our popular PEEK material as one of the toughest in aggressive applications. By studying specific application needs Freudenberg-NOK has developed an expertise in thermoplastic technology, has patented part designs and has developed proprietary manufacturing processes that deliver precision components.

Refining sealing ring standards, solving historic problem areas with application experience and coordinating with global partners are all in a day’s work.

Technical Feedback

With all of this activity at the OEM level, it is only natural that this collective experience as the world leader in seal manufacturing translates into expertise in the aftermarket. In every case, technological advances learned from not only past research but also feedback from the field is considered during new kit development. We attend seminars and trade shows around the world where we have the opportunity to network with transmission professionals one-on-one. In addition, we have strategically placed five regional account managers across North America who are making regular shop visits to collect information and provide technical support where needed. We have also built strong relationships with a number of volume rebuilders who we work closely with.

But why gather all this feedback? Because we are constantly looking for ways to add more value to what’s in our bag. That is, we want to provide the most complete, highest quality kit to the market. Whether that be with new designs, new materials or a combination of both it is our goal to make TransTec® the first choice for automatic transmission overhaul kits. When you see the familiar black and gold package with the TransTec® name on it, you’ll know it contains only quality components; quality that meets or exceeds OE requirements. You’ll know you can trust that from initial design to testing to manufacturing and finally installation, Freudenberg-NOK has dedicated a wide range of resources to ensure what’s inside the bag will stand the test of time.

Advancing Technologies

With the advancement of technology, there come additional challenges to make sure we’re providing time-sensitive, relevant products and information to the field. In pursuit of this, we strive to be first-to-market with new product introductions. And when we do bring a kit to market, it is the most complete, accurate kit avail-able. We take painstaking measures to ensure that our research and development teams identify every sealing component that will be required to rebuild a particular unit. We work together in teams to provide a check and balance to the process. From initial teardown to analyzing, identifying, engineering and sourcing each individual part the team members continually check and recheck. During this entire process, the team is gathering comprehensive application knowledge so that we can support end-users with the best technical services.

Something new we’ve added is a video recording of the teardown process. The ability to reference the original application analysis and teardown is immensely beneficial when our product team answers questions that arise from the field. And we’ve taken that one step further. We are now creating YouTube videos that can be viewed by technicians around the globe. While these videos are not meant to instruct viewers how to rebuild a unit, they are more simply designed to highlight uncommon or significant findings in a particular transmission. We’re providing QR codes right on the package so when a technician has the unit on his bench, he can easily scan the code to view a short video. Links can also be found on our website www.transtec.com or by subscribing to our YouTube channel, 1TransTec.

We’re not just about Transmissions

PTFE rings and engineered solutions are not only applied in TransTec® transmission products, but can also be found in the TransTec® power steering product offering. In the hydraulic power steering environment all seals are subjected to extreme pressures and heat. Freudenberg-NOK’s proprietary compounds are specifically formulated to meet the various sealing requirements of both rotational applications such as hydraulic control valves and hydraulic power steering pumps, as well as reciprocating applications such as hydraulic pistons. In addition to dimensional requirements, a combination of pressure, heat, mating surface materials and directional requirements will dictate the specific PTFE compound that is used.  Incorporating the same precision used in OE manufacturing processes as well as the full depth of Freudenberg-NOK technology to the TransTec® steering products is what sets the brand apart from all other aftermarket products, and signifies that we are not just another parts provider, but a manufacturer of engineered solutions.

Incorporating the same precision used in OE manufacturing processes as well as the full depth of Freudenberg-NOK technology to the TransTec® steering products is what sets the brand apart from all other aftermarket products, and signifies that we are not just another parts provider, but a manufacturer of engineered solutions.

Trust TransTec®

There’s a reason why transmission professionals install more TransTec® kits than all other kits combined. Since 1978 when the brand was founded, the objective has been to provide the independent aftermarket with the most comprehensive, highest quality kits available. In an industry that has seen significant change and many challenges, the original brand promise that made it the preferred brand has been maintained and has stood the test of time. Now a global brand, TransTec® kits are brought to you by Freudenberg-NOK a technology leader and global manufacturer of precision sealing products. Freudenberg, NOK and Freudenberg-NOK together have over 120 facilities in 56 countries worldwide, producing seals and components for virtually every auto manufacturer in the world. These resources alone position the TransTec® brand to be on the cutting edge of technology and product development.

About Freudenberg-NOK Sealing Technologies

Freudenberg-NOK Sealing Technologies runs the operative business of Freudenberg Sealing Technologies (FST) in the Americas. Being part of the global Freudenberg Group, the company is a leading producer of advanced sealing tech-nologies for a variety of markets including: aerospace; agriculture; appliance; automotive; construction; diesel engine; energy; food and beverage; heavy industry; and pharmaceutical. Freudenberg-NOK Sealing Technologies a joint venture between FST and NOK Corp. in Japan, is headquartered in Plymouth, Mich. and operates more than 20 facilities across the Americas. For additional information, please visit www.fst.com.