Gone is the LCT1000, and in its place is the 10L1000 transmission. GM has fully embraced its new 10-speed unit as the high torque capacity option and placed it behind its workhorse engine, the Duramax diesel, in 2020. With this transmission already logging hundreds of thousands of miles in its five years of existence, it has shown some promising signs of being a formidable replacement. However, some issues bring these units into the shop in need of repairs. Let’s explore what kind of issues this transmission is having, as well as the available fixes.

UNIT ID

The Duramax diesel engine is the most common power plant that is paired with the 10L1000. However, in 2024, General Motors offered this transmission with the 6.6-liter (RPO L8T) gasoline engine. Both powertrain options are only available in heavy-duty applications. The 10L1000 transmission option can easily be identified by RPO codes MGM and MGU. Both applications are available in two-wheel drive or four-wheel drive configurations.

SHIFT QUALITY ISSUES

Shift quality issues are the most prevalent concern with this unit. While most of the problems lie in the valve body, worn or failing components inside the transmission may also be the culprit. Whenever you are diagnosing for shift quality concerns with the 10L1000, always make sure that you scan for all codes in all modules and address them first. Also, ensure that the powertrain (ECM and TCM) module programming is updated to the latest level of software. Further, note that sensors reading out of range will produce shift quality issues without setting codes. Concerns of shuddering, binding, slipping, and/or flared, erratic, and harsh shifts may occur without setting diagnostic trouble codes. Issues may be intermittent or persistent. Areas of concern aside from the valve body are as follows:

- F-clutch drum spline wear

- E-clutch assembly wear and damage

- Failing speed sensors

The transmission strategy is programmed to correct poor shift quality. So, sometimes the strategy will mask internal damage, such as clutch spline wear that causes clutch drag. Speed sensor-related faults can be monitored by back-probing the sensor signal circuits and monitoring them with a digital storage oscilloscope (DSO).

The transmission strategy is programmed to correct poor shift quality. So, sometimes the strategy will mask internal damage, such as clutch spline wear that causes clutch drag. Speed sensor-related faults can be monitored by back-probing the sensor signal circuits and monitoring them with a digital storage oscilloscope (DSO).

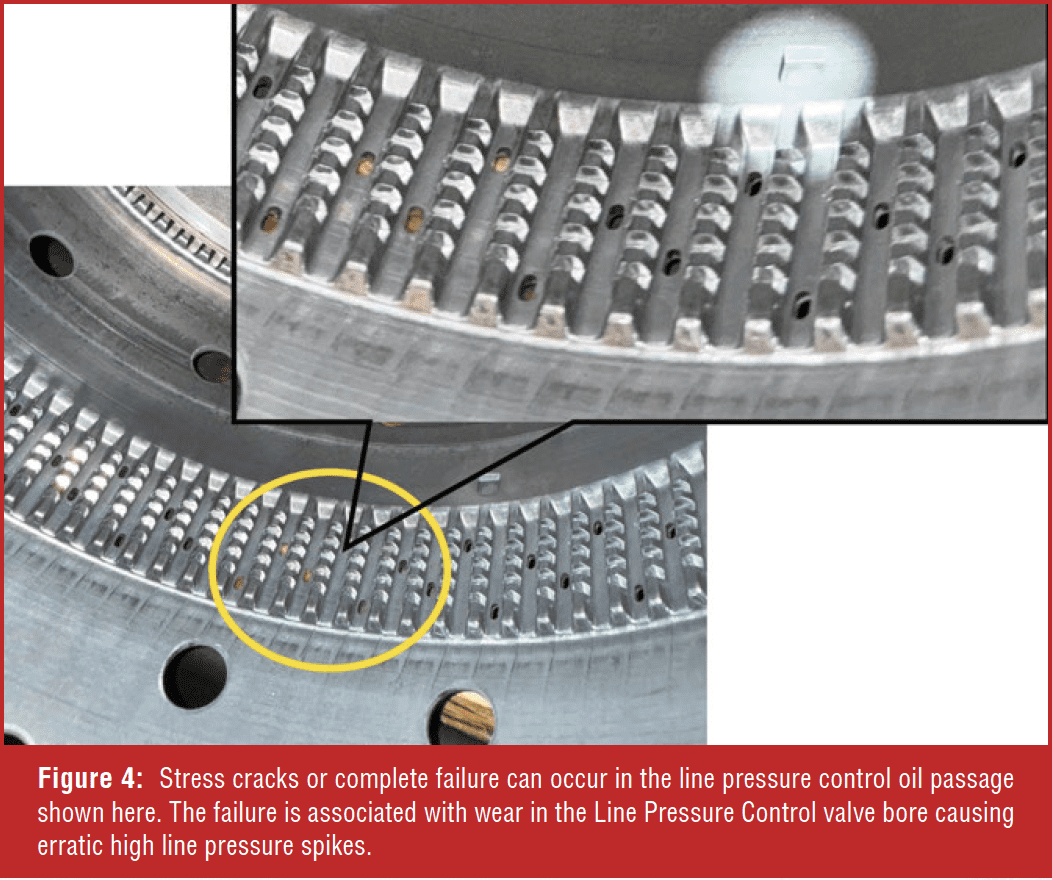

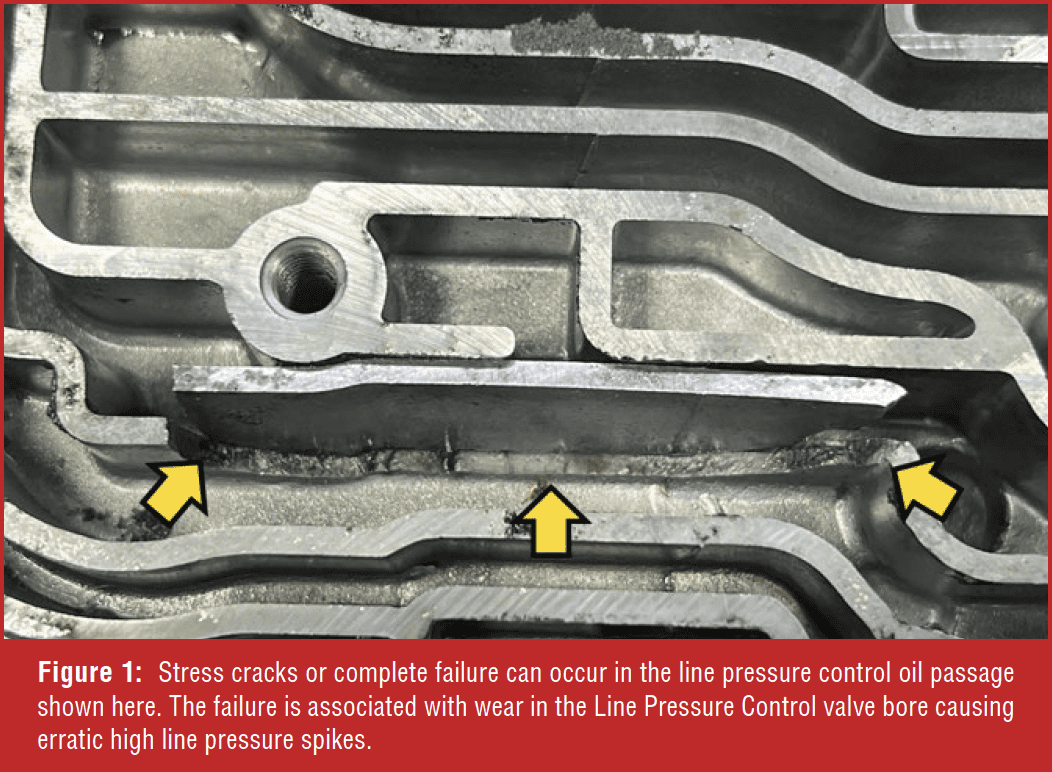

Unstable line pressure tops the list of items of concern inside the valve body. The main line pressure regulator bore wears, which creates a loss of accurate control of line pressure at the EPC Solenoid, resulting in high line pressure spikes. The high line pressure spikes can crack , or break valve body passages (Figure 1). Always inspect early valve body castings for cracked or failing passages. Temperaturesensitive faults, such as binding in reverse or harsh/erratic shifts that only occur when the unit is hot but work well when cold, usually indicate a cracked valve body. GM has updated the casting with thicker passage walls. Note that there is currently no firstor second-generation variant for the 10L1000.

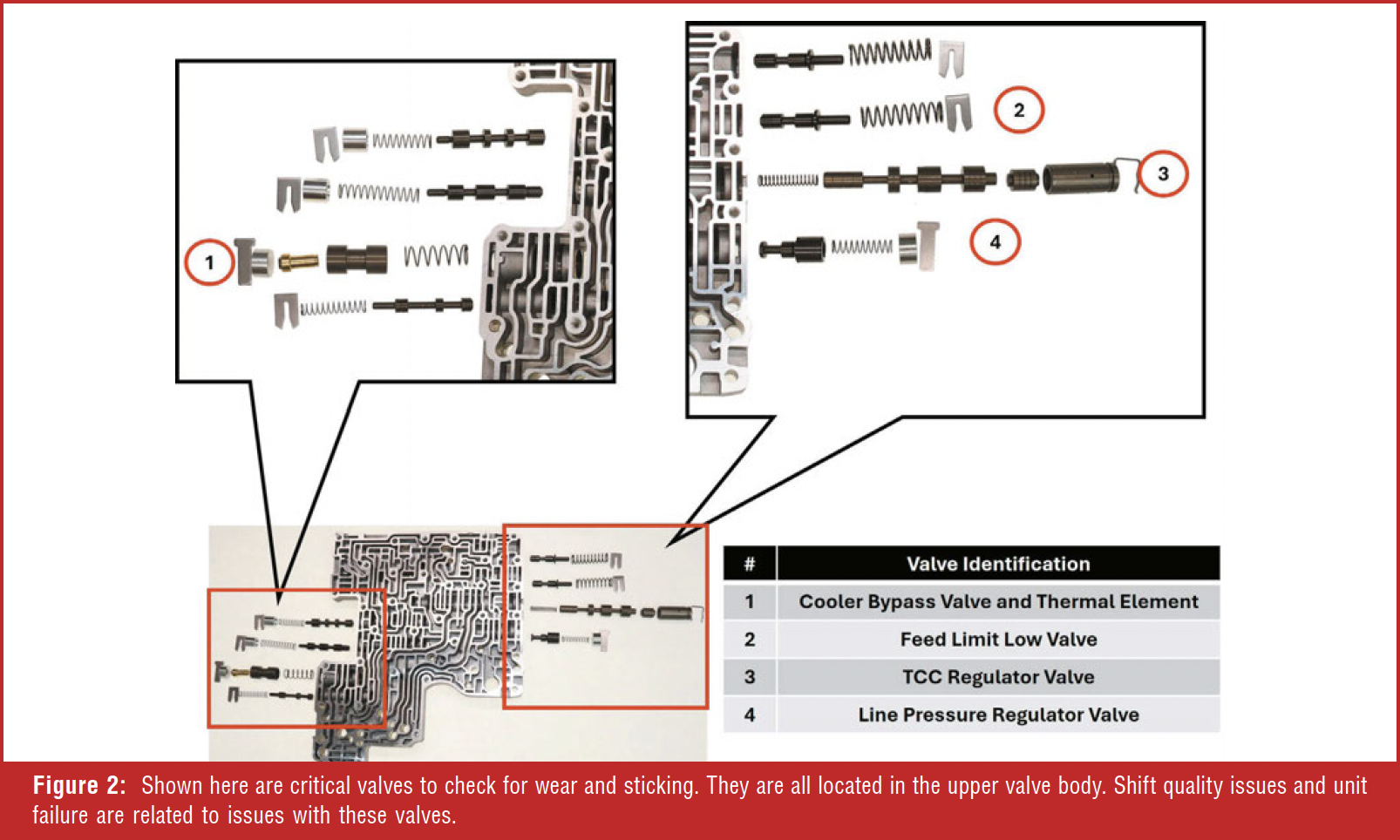

Another major concern is a momentary rear wheel locking condition, which may occur with or without diagnostic trouble codes. GM issued a safety recall for this concern (recall number N242480630). A possible DTC P0747 (Pressure Control Solenoid’ A’ stuck on) may be stored in the TCM memory. The symptom observed would be the vehicle cruising at highway speeds in a higher gear range and suddenly being commanded to downshift to 2nd gear without notice. Another symptom may be that the transmission is stuck in 5th gear. These concerns are related to excessive wear in the Feed Limit Low valve bore (Figure 2). The loss of control oil in this circuit causes the default disable hydraulic circuit to activate ‘limp mode’ without the Default Disable solenoid changing state.

There is an aftermarket repair available through your parts supplier. However, be aware that the TCM programming must be checked to ensure the latest software is downloaded. The update ensures that if a repeat failure occurs in the future, the unit will command 5th gear instead of 2nd. Repair or replace the valve body as needed.

Other issues that occur on the valve body side also revolve around wear concerns. Worn or sticking Clutch Regulator Control valves are common if the unit has metal or excessive clutch debris in the transmission fluid. The control valves do not have return springs behind them, but they rely on Exhaust Backfill oil pressure constantly directed behind the valve to keep the valve pushed toward the solenoid. Since all the clutch supply oil passes through these valves, any restriction in the movement of these valves will affect shift timing and quality.

Other issues that occur on the valve body side also revolve around wear concerns. Worn or sticking Clutch Regulator Control valves are common if the unit has metal or excessive clutch debris in the transmission fluid. The control valves do not have return springs behind them, but they rely on Exhaust Backfill oil pressure constantly directed behind the valve to keep the valve pushed toward the solenoid. Since all the clutch supply oil passes through these valves, any restriction in the movement of these valves will affect shift timing and quality.

Sticking linear pintle solenoids are another concern. Again, if there is excessive debris, especially ferrous metal in the fluid, it will gravitate towards the control solenoids because they are effectively electromagnets. Individual replacement solenoids are not available. However, good used solenoids are readily available. Ensure that your replacement solenoid characteristic number matches the original solenoid you are replacing.

Broken or weak solenoid retaining clips plague this unit. If you are servicing the valve body or rebuilding the unit and using the original valve body, always replace the solenoid retaining clips. There are OEM and aftermarket solutions to service the retaining clips. If the vehicle had erratic shifts or other shift quality-related concerns, and the solenoid retaining clips were loose or broken, thoroughly inspect the area of the valve body closest to the valve for excessive wear. The linear pintle solenoids are pulsewidth modulated and oscillate on and off to move the hydraulic clutch control valve mechanically. Oscillation can create a vibration and movement of the solenoid body, causing wear in the valve bore area. If excessive wear is observed, the valve body needs to be replaced.

Finally, a thorough assessment of the Torque Converter Clutch valve train. Check for bore and sleeve wear and freedom of movement. You must perform a collective evaluation of the valve body to determine if repair or replacement is best. GM references several part numbers for the valve body. Always use the latest, updated casting.

INTERNAL COMPONENT WEAR

INTERNAL COMPONENT WEAR

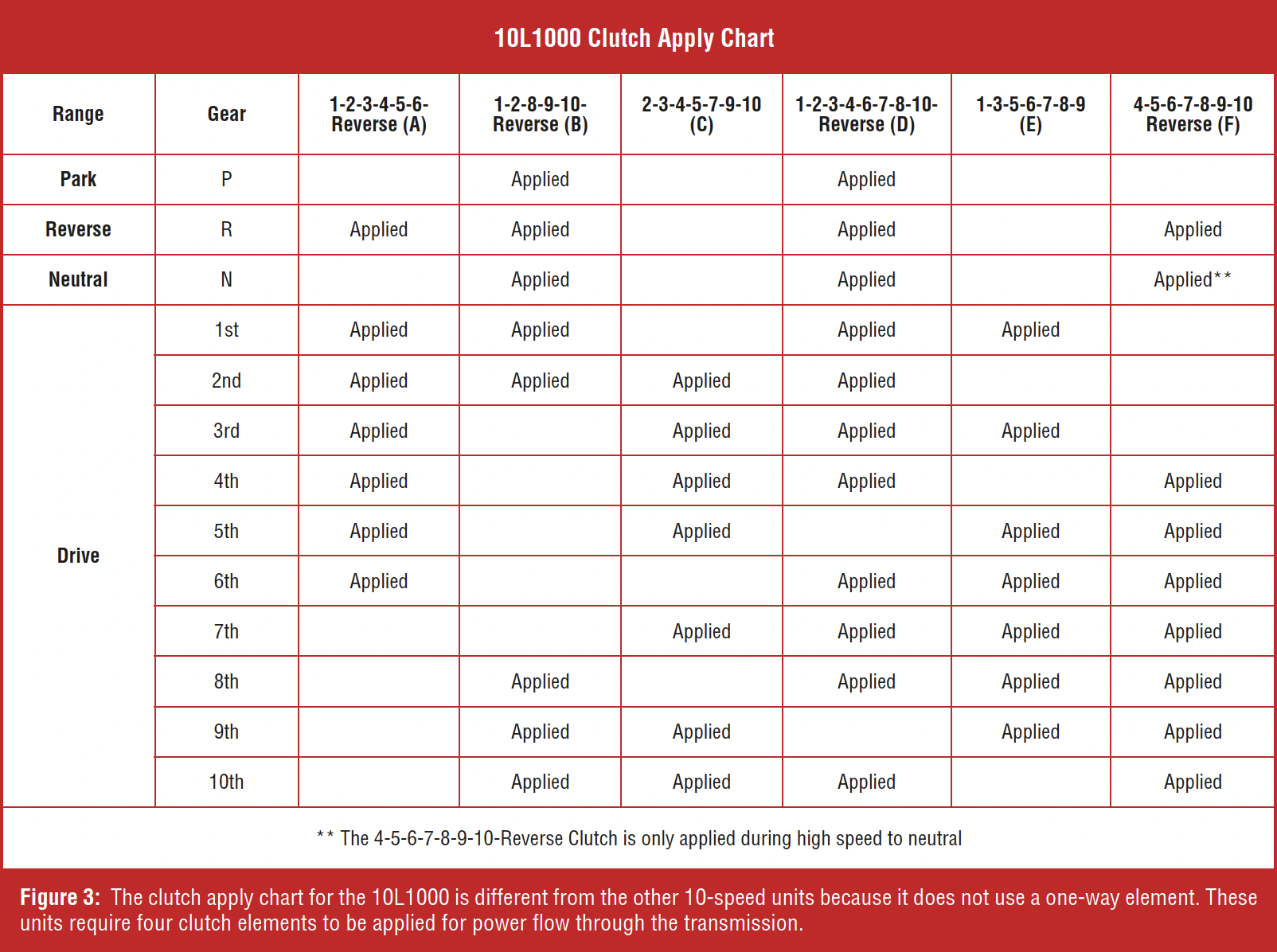

As mentioned earlier, failing internal parts can cause erratic shift quality issues. Use the clutch apply chart to help isolate mechanical faults (Figure 3). Keep in mind that this unit requires four clutch components to be applied for power flow. So, if you’re diagnosing for a bind or movement in neutral, you should look for a clutch that should not be applied. The following concerns may indicate internal component damage or failure:

- Vehicle moves forward with power in Neutral

- Binding

- Erratic shifts

- Harsh/slipping shifts

Like its smaller sibling unit, the 10L1000 shares concerns about internal component wear. However, since this unit is in heavier vehicles, the damage observed is often more severe. Let’s take a closer look at what’s happening inside this unit.

The 4-5-7-8-9-10-Rev (F) Clutch Drum

The F-clutch drum, more commonly known as the ‘trash can’, is prone to wear in the clutch spline area (Figure 4). A total failure of the splines results in a ‘no reverse’ complaint. The part is available from GM; however, it is usually on back order (P/N: 24048634). Several aftermarket companies make a heavy-duty version of this part. Most of them have an anodized coating to strengthen the wear areas. It is recommended to use the aftermarket version of this part if the vehicle is used for heavy towing or high performance.

The 1-3-5-6-7-8-9 (E) Clutch Assembly

The 1-3-5-6-7-8-9 (E) Clutch Assembly

Burnt E-clutches were one of the first issues that brought the early 10L1000 units into shops. It was later discovered that the E-clutch housing was flexing under high loads, causing an uneven application of the clutch pack. The clutches failed prematurely as a result. Also, the steel clutch disc teeth would dig into the aluminum hub, causing clutch drag. Several aftermarket solutions are available for this assembly. Search online or use your local soft part supplier to locate parts.

The 2-3-4-5-7-9-10, 1-2-3-4-6-7-8-10-Rev, 4-5-7-8-9-10-Rev (CDF) Drum

Another possible area of failure in this unit involves the CDF drum. Although it is not as common as in the Ford 10R80 units, it does occur, and you must check this drum. Most failures are attributed to the unit operating over temperature for extended periods of time. So, if the unit came in with overheating concerns, there is a high possibility that this drum may be damaged. Check for movement of the internal sleeve where the sealing rings ride.

Also, note that the parts in this transmission are not inexpensive. As a matter of fact, when you search for the aftermarket parts, you may be shocked by the prices. Don’t be scared to price the job accordingly. You want to do it only once, so do it right. Keep in mind that a replacement vehicle will cost at least $75,000 or more!

OVERHEATING

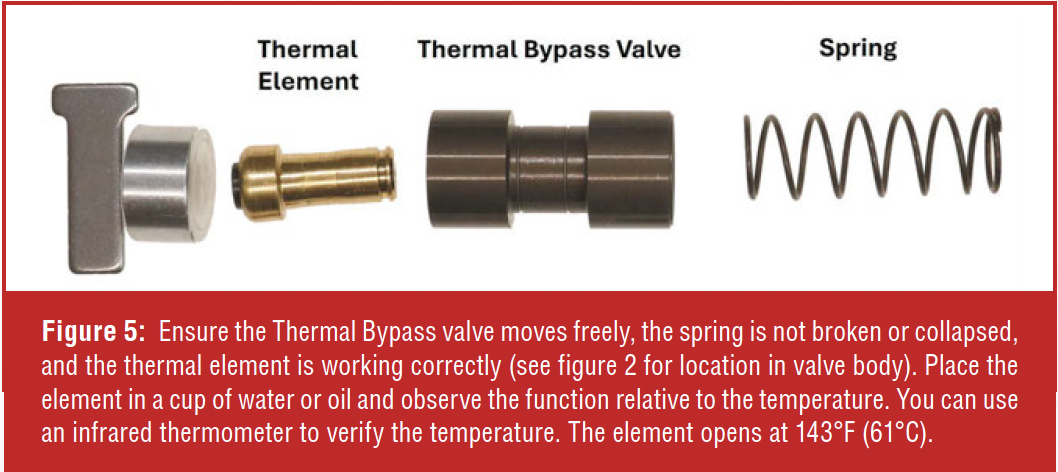

Transmission overheating is another concern. The thermal bypass valve can stick, or the element can fail (Figure 5). It is not recommended to disable the thermal bypass valve in this transmission. Remove, clean, and inspect. Test the thermal element to ensure that it expands and contracts at the recommended temperature range. Repair and replace as necessary.

Also, the transmission cooler lines may be restricted due to incorrect installation by the factory. Check the rubberized hoses to ensure they are not kinked. If the vehicle is equipped with a warmer and the unit suffered a catastrophic failure, causing severe metallic contamination, the warmer element must be replaced. Only use Dexron ULV transmission fluid in the 10L1000. Incorrect fluid will cause overheating as well as shift quality issues and torque converter clutch shutter.

Also, the transmission cooler lines may be restricted due to incorrect installation by the factory. Check the rubberized hoses to ensure they are not kinked. If the vehicle is equipped with a warmer and the unit suffered a catastrophic failure, causing severe metallic contamination, the warmer element must be replaced. Only use Dexron ULV transmission fluid in the 10L1000. Incorrect fluid will cause overheating as well as shift quality issues and torque converter clutch shutter.

General Motors made a bold step in launching its latest technology behind its most powerful engines. While there are some growing pains with the 10L1000, it proves to be an adequate replacement for its predecessor. With the support of the aftermarket, transmission shops will be able to confidently deliver the goods to their customers, knowing they built a solid, reliable unit!