The aftermarket automotive service industry has been pushing scope usage for decades. Driveability shops have invested thousands of dollars into PC based scopes or scan tools with scoping abilities, but is it all necessary? For a transmission shop, it can be hard to justify spending $3000+ on a tool that might end up collecting dust in the bottom of a toolbox. Let’s face it, many transmission issues can be diagnosed with a scan tool, multimeter, or heck, even a test light. But I’m sure you have probably questioned yourself numerous times on what a suspect signal or command “looks like.” Is there interference or noise on that circuit? Does the power cut out? Is that solenoid mechanically switching on and off? What does the current flow actually “look” like? What’s the pressure actually doing during the shift?

Or you might dabble in areas outside of transmission repair and wonder if there is an easier way to check compression quickly. Did that engine jump time? Is there an exhaust restriction? Why doesn’t my scan tool communicate? I wonder what that CAN signal looks like? There are many circumstances where a scope would be beneficial. If you don’t already have a scope and price is the major holdback, then I have a question for you: If you could spend less than $500, would you consider getting into the scoping game?

Or you might dabble in areas outside of transmission repair and wonder if there is an easier way to check compression quickly. Did that engine jump time? Is there an exhaust restriction? Why doesn’t my scan tool communicate? I wonder what that CAN signal looks like? There are many circumstances where a scope would be beneficial. If you don’t already have a scope and price is the major holdback, then I have a question for you: If you could spend less than $500, would you consider getting into the scoping game?

This article compares four scopes to see if they can adequately perform some of the most common automotive measurements. We’ll be looking at the following scopes (figure 1): Hantek 6022BE 2-channel ($60), PICO 2204a 2-channel ($140), AUTEL MaxiScope MS408 4-channel ($400), and the PICO 4425 4-channel ($1600). With each of these scopes, you can download the software for free off their respective websites.

To conduct this comparison, I outfitted a 2014 GMC Sierra pickup truck with test leads hooked up to the most common circuits tested with scopes. Now we can see if each of these tools has the capability of accurately measuring these circuits.

To conduct this comparison, I outfitted a 2014 GMC Sierra pickup truck with test leads hooked up to the most common circuits tested with scopes. Now we can see if each of these tools has the capability of accurately measuring these circuits.

First, let me disclose that I am not comparing apples to apples, but I don’t think I need to. The ultimate question is, can scope A perform the same measurements as scope B (and C and D)? Some specifications exist between these scopes that make one piece of hardware more powerful than the next, and the software available for these scopes will make some scopes easier to operate and more functional.

Let’s look at scope resolution, for example. The Hantek and the Pico 2204a are 8-bit scopes, while the Autel and the Pico 4425 are 12-bit scopes. That resolution spec covers the clarity of the graph it displays and will affect the scope pattern’s appearance when you “zoom in.” figures two and three demonstrate the difference in resolution by showing an 8-bit graph with only 256 cells versus a 12-bit graph with 4096 cells. That’s 16 times more clarity in the 12-bit graph.

Pico 4425 vs. Autel MS-408 vs. Pico 2204a vs. Hantek 6022BE

Pico 4425 vs. Autel MS-408 vs. Pico 2204a vs. Hantek 6022BE

A while ago, I surveyed technicians on Facebook to figure out the most common uses for a scope. Of course, I had my favorite uses, but they are typically off-the-wall applications, like vibration analysis, pressure, and pulse testing using shop-made tools. I wanted to know how the average tech uses their scope in day-to-day diagnostics. This article will be a two-part series, and in part one, you’ll see all four scopes measuring relative compression, in-cylinder pressures, and cam/crank correlation. In part two, you’ll see the scopes measuring ignition primary/secondary, injector amperage/ voltage, CAN bus, and transmission line pressure.

Relative Compression:

Relative Compression:

The number one scope use from my informal survey was relative compression, and it is a measurement that can quickly tell the technician if there is an engine mechanical problem. To perform the test, hook a high-amp current clamp around the battery cables and crank the engine over with the fuel disabled. The resulting pattern will show how much current each cylinder is requiring during the compression stroke. The same measurement can be done with voltage, but you either need to set the scope to AC volts (so you can adequately see the oscillations), or you need a scope that can “zoom in” on the DC voltage pattern. The Pico 4425 (figure 4) did great with DC voltage as well because the zoomed-in DC pattern shows the voltage dropping each time a cylinder is compressing the air/fuel charge. Interesting note: voltage is the exact opposite of the amp clamp reading, and if you can invert the signal, it will overlay exactly on the amperage pattern. I think this is great because if you’re like me, 90% of the time, when I grab an amp clamp, the battery is dead from me accidentally leaving it on.

I think this is great because if you’re like me, 90% of the time, when I grab an amp clamp, the battery is dead from me accidentally leaving it on.

The Autel (figure 5) did great with the amp clamp, but since it doesn’t allow the tech to zoom in on a single channel like the Pico software, you should set the channel’s voltage coupling to AC and set the volts per division to +/- 500mv to adequately see the oscillations. When performing a relative compression and measuring the voltage, the oscillations are not as dramatic, so that’s why it’s important to use AC coupling unless you can zoom in on a single channel. The Pico 2204A (figure 6) did great with amperage, but it also needed to be set on AC for voltage.  Not because you couldn’t zoom in on a single channel (you can), but because the signal resolution is too low (recall the 8-bit discussion from above) so that when you zoom in, the pattern becomes pixilated. Lastly, the Hantek (figure 7) did fine with the amp clamp, but it required a physical “AC filter” to test with voltage because the scope software doesn’t allow you to select AC coupling. This is a huge negative for this scope, although using an AC filter is a good workaround. The AC filter can be made from a non-polarized capacitor, or you can purchase an adapter that fits in line with your test leads. The purpose of the AC filter is to only allow AC voltage through and block all DC. With the filter, you can set the scope to DC +/-500mV, and then you can see the voltage oscillations resulting from the compression because the filter blocks out the DC voltage and only passes the AC voltage. This adaptor is only necessary if you cannot select AC coupling on your scope, which was the case with the Hantek.

Not because you couldn’t zoom in on a single channel (you can), but because the signal resolution is too low (recall the 8-bit discussion from above) so that when you zoom in, the pattern becomes pixilated. Lastly, the Hantek (figure 7) did fine with the amp clamp, but it required a physical “AC filter” to test with voltage because the scope software doesn’t allow you to select AC coupling. This is a huge negative for this scope, although using an AC filter is a good workaround. The AC filter can be made from a non-polarized capacitor, or you can purchase an adapter that fits in line with your test leads. The purpose of the AC filter is to only allow AC voltage through and block all DC. With the filter, you can set the scope to DC +/-500mV, and then you can see the voltage oscillations resulting from the compression because the filter blocks out the DC voltage and only passes the AC voltage. This adaptor is only necessary if you cannot select AC coupling on your scope, which was the case with the Hantek.

In conclusion, if you have a high-amp current clamp, all of the scopes worked very well. It’s also worth mentioning that both Pico and the Autel allow the tech to filter the pattern to clean up a noisy scope capture. That’s handy when performing measurements using inductive or capacitance clamps or when using a low-voltage setting on the scope. The Hantek doesn’t have a filter with their software.

In-Cylinder Pressure Testing:

On my survey, in-cylinder pressure testing was another commonly indicated use for a scope. Using in-cylinder compression testing with a scope provides much more information than simply using a standard gauge. The technician can measure exhaust backpressure, check valve opening and closing events, monitor intake vacuum, check for cylinder sealing, and, of course, check for adequate compression. The Pico (figures 8 & 10) and Autel (figure 9) scopes did a great job with the in-cylinder pressure testing. The Pico has some in-house pressure transducers already loaded in their software. Both the Pico and Autel include the ability to add “custom probes,” where you teach the software how any transducer works, and then the scope will display the actual measurement values to indicate PSI, KPa, or whatever your favorite pressure unit is.

The Hantek wasn’t really cut out for pressure testing. The transducer I used (Fluke PV350) introduced a lot of noise, and there was no way to filter it out. The Pico and Autel scopes can filter signals, which made the pattern useable. Another awesome feature that Pico and Autel provide with their software is “degree rulers.” The degree rulers allow the technician to drag two vertical rulers that identify degrees of rotation. You can type in whatever degrees you want, so in the examples shown, you can see (figures 8, 9, & 10) I used “0” and “720” (to represent the four-stroke cycle). You can add additional rulers to create divisions between the degree rulers, and you can even use the traditional time rulers to measure degrees of valve events. This is very handy to see if the cam is out-of-time.

The Hantek wasn’t really cut out for pressure testing. The transducer I used (Fluke PV350) introduced a lot of noise, and there was no way to filter it out. The Pico and Autel scopes can filter signals, which made the pattern useable. Another awesome feature that Pico and Autel provide with their software is “degree rulers.” The degree rulers allow the technician to drag two vertical rulers that identify degrees of rotation. You can type in whatever degrees you want, so in the examples shown, you can see (figures 8, 9, & 10) I used “0” and “720” (to represent the four-stroke cycle). You can add additional rulers to create divisions between the degree rulers, and you can even use the traditional time rulers to measure degrees of valve events. This is very handy to see if the cam is out-of-time.

Conclusion: The Pico and Autel really shine when performing in-cylinder pressure testing. The ability to set up custom probes makes it easy to tell vacuum and pressure. The degree rulers allow for precise measuring of cam events and the four-stroke cycle. The Hantek wasn’t really up to the task for this process.

Cam and Crank Correlation and Shape:

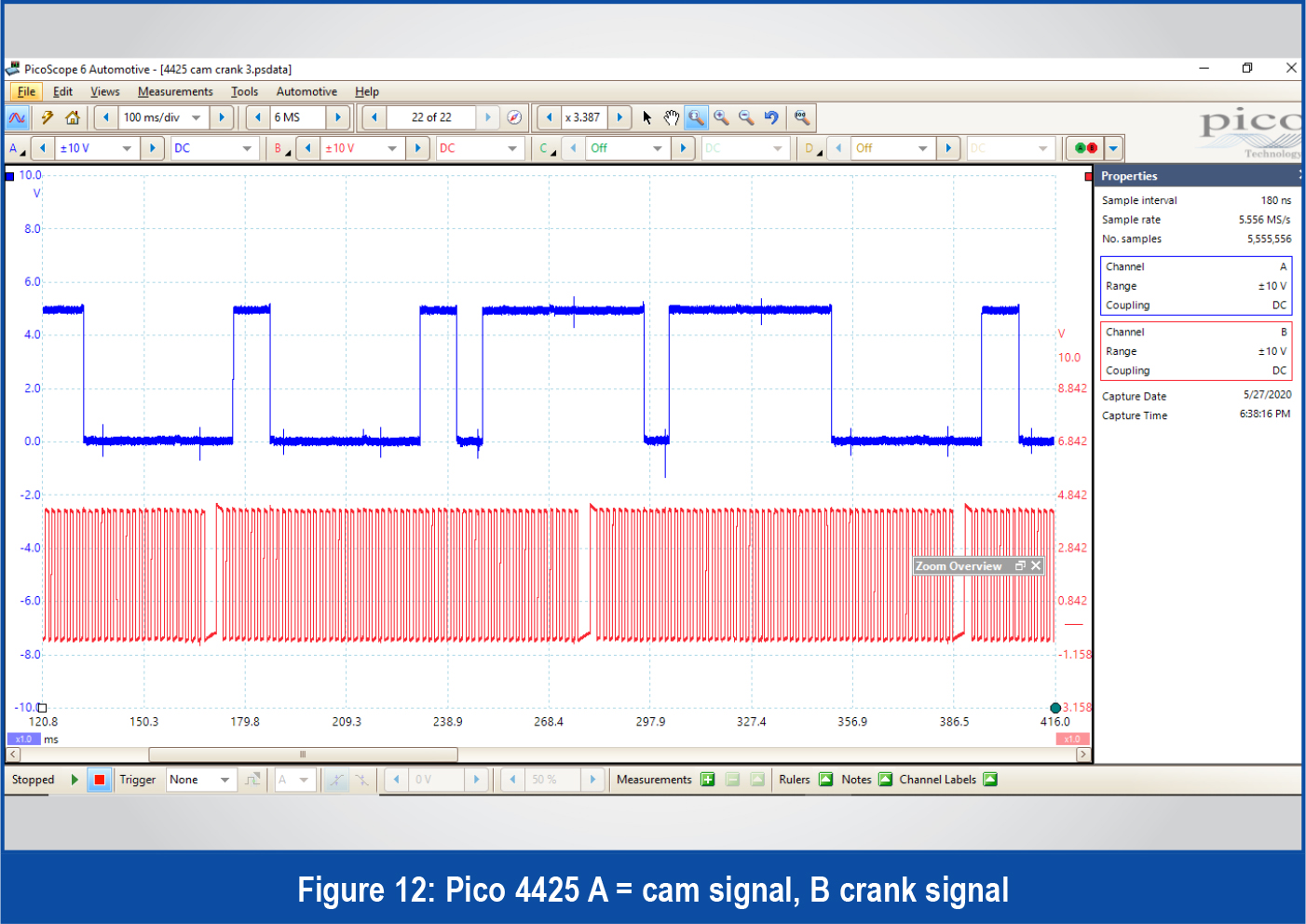

Another common use for a scope is Cam and Crankshaft signal correlation. The ability to line up the cam and crank signals and also to evaluate the actual pattern is a huge benefit of a scope. As you can see, all the scopes did a fine job with the cam and crank signal. A few things that are worth noting, the Pico and the Autel scopes allow the technician to save the scope traces. Also, the software “buffers” and records multiple screens of scope data, so when you stop the capture or save the capture, you can save multiple screens for future review. The buffered screens function is great when you see the fault, and then by the time you stop the pattern, it’s off the screen. Now you know it’s still there and saved as a previous screen. The ability to save the scope images is a great feature when you want to compare a vehicle to one that you’ve had in the past. It also allows for sharing of scope captures through the web and email.

Conclusion: All of the scopes showed the cam and crank patterns well. The Pico 4425 and the Autel are four-channel scopes, so you can compare more signals at once (figures 12 and 13). The Pico and Autel software also have an advanced pattern triggering function that allows the technician to stabilize the pattern, so it’s not jumping around the screen. My personal preference is to put a lot of time on the screen (5 sec or so) and just zoom in to view the patterns, so I don’t use triggers that much (figure 14 and 15).

That’s enough comparing for this article. Next month, look for part two, where these scopes will go head-to-head performing measurements on ignition primary and secondary, injector voltage and amperage, CAN bus, and transmission pressures. So far, going off of the scope images provided, that inexpensive Pico 2204a isn’t looking too bad!