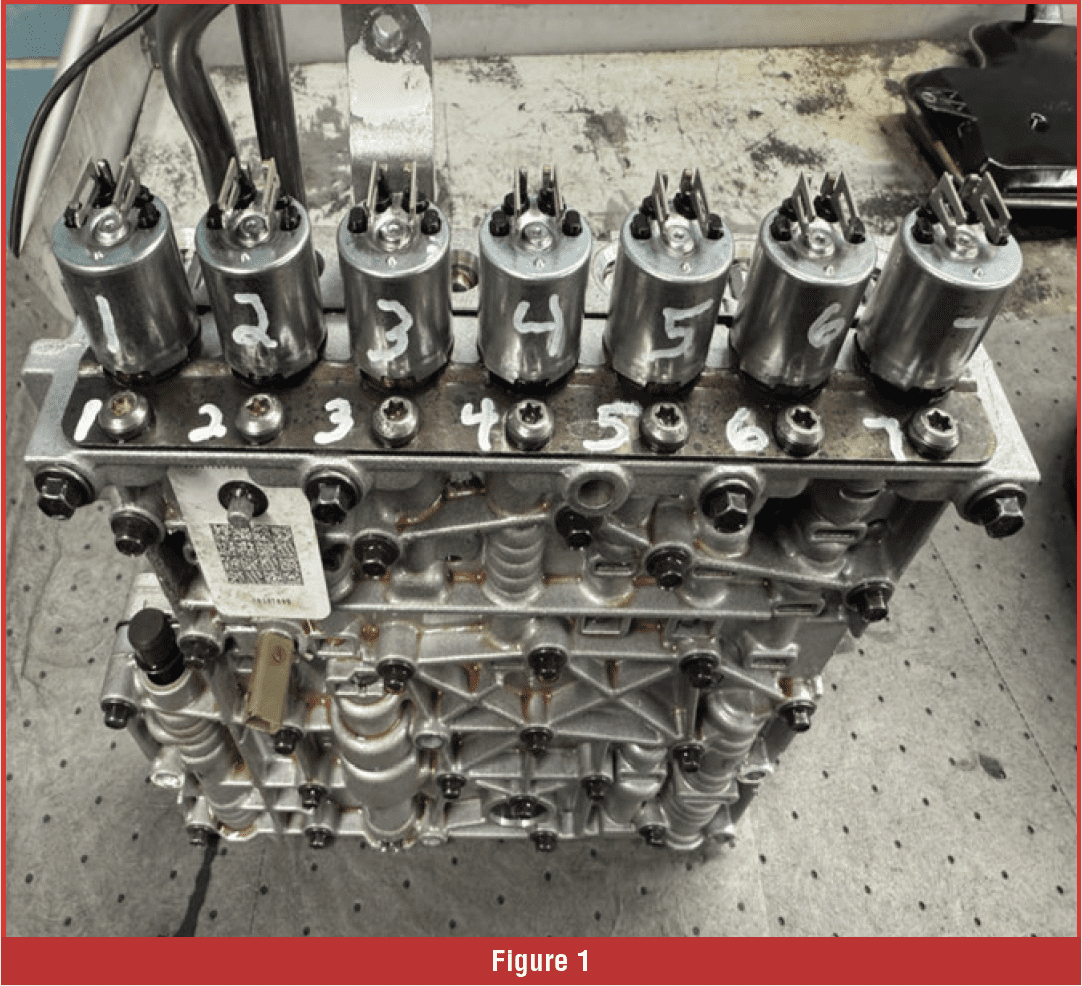

Conventional gasoline vehicles used gear trains to provide a torque multiplication and also provide low, medium, and high speeds for the vehicle. Conventional vehicles of the past had only two speeds, whereas modern transmissions now have up to 10 speeds. Why do we keep adding gears to the transmission? A couple of contributing factors are that we can keep the engine in its torque band when we need maximum torque, and we can increase fuel mileage by lowering the engine’s RPM. Transmissions on the way to 10 speeds became increasingly sophisticated, and they became larger due to the addition of more parts. Let’s turn our attention to the electric vehicle. Most of us would consider an electric vehicle (EV) a sophisticated piece of machinery. When we look at the transmission, we find that most electric vehicles have only single-speed gearboxes. How is that possible when its gasoline counterpart has 6-10 speeds? As stated previously, gasoline models must keep the engine within its torque range while allowing the vehicle to travel at varying speeds. Let’s look at how many solenoids are used on a 6R140 with only six speeds and lockup (Figure 1).

Conventional transmissions must provide a range of gear ratios to achieve the desired torque output and a speed of 100 mph or higher. An EV can provide the desired torque and obtain speeds of 100 mph with a single-speed transmission. What makes this possible is that the three-phase motor develops maximum torque as soon as it rotates. It maintains that torque until it reaches approximately 6,000 RPM (Figure 2). Electric motor torque is directly related to supply voltage. Increasing the supply voltage will increase the motor’s torque. You could say motor torque is controlled by the voltage supply, and the voltage frequency controls motor speed. Gasoline engines develop torque on a curve; the torque starts to develop at a lower RPM and continues to increase until max torque is reached. With many engine families, this may be in the 4,000 RPM range and will start to diminish based on volumetric efficiency (VE). Electric motors start to lose torque based on back electromotive force (EMF). Electrical training has taught us that when a magnet is spun inside a coil of wire, it produces a voltage.

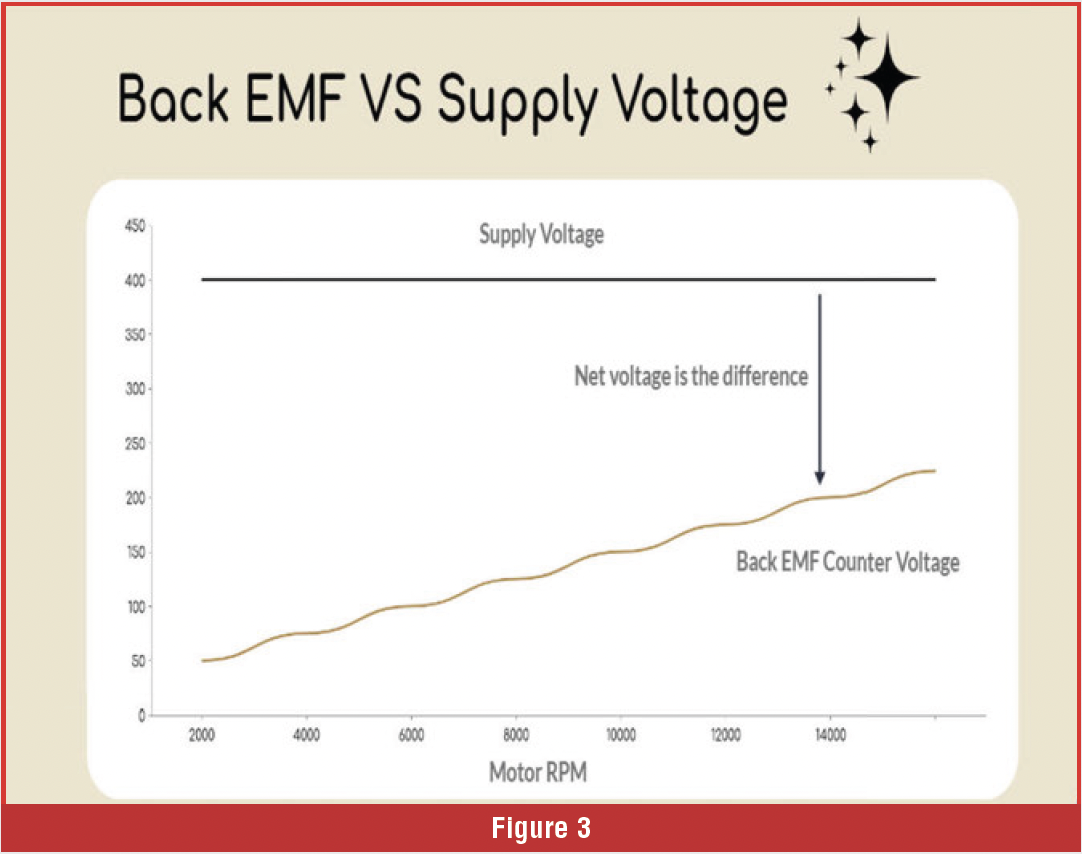

Conventional transmissions must provide a range of gear ratios to achieve the desired torque output and a speed of 100 mph or higher. An EV can provide the desired torque and obtain speeds of 100 mph with a single-speed transmission. What makes this possible is that the three-phase motor develops maximum torque as soon as it rotates. It maintains that torque until it reaches approximately 6,000 RPM (Figure 2). Electric motor torque is directly related to supply voltage. Increasing the supply voltage will increase the motor’s torque. You could say motor torque is controlled by the voltage supply, and the voltage frequency controls motor speed. Gasoline engines develop torque on a curve; the torque starts to develop at a lower RPM and continues to increase until max torque is reached. With many engine families, this may be in the 4,000 RPM range and will start to diminish based on volumetric efficiency (VE). Electric motors start to lose torque based on back electromotive force (EMF). Electrical training has taught us that when a magnet is spun inside a coil of wire, it produces a voltage.  Electric motors start to develop a counter voltage, known as back EMF, as the magnetic rotor begins to spin inside the stator, which is a coil of wire. The voltage that it produces by the rotor counteracts the supply voltage. For example, if the back EMF created by the motor were 200 volts and the supply voltage were 400 volts, you would end up with a net voltage of 200 (Figure 3). The net voltage is what is left to drive the motor. As the net voltage decreases, the torque of the electric motor decreases. Electric motors are way more efficient from 0 to 6,000 RPMs than they are from 6,000 RPMs and up. The higher the supply voltage, the more back EMF you can handle, which is possibly why the industry is moving from the 200-400 volt batteries to an 800 volt battery.

Electric motors start to develop a counter voltage, known as back EMF, as the magnetic rotor begins to spin inside the stator, which is a coil of wire. The voltage that it produces by the rotor counteracts the supply voltage. For example, if the back EMF created by the motor were 200 volts and the supply voltage were 400 volts, you would end up with a net voltage of 200 (Figure 3). The net voltage is what is left to drive the motor. As the net voltage decreases, the torque of the electric motor decreases. Electric motors are way more efficient from 0 to 6,000 RPMs than they are from 6,000 RPMs and up. The higher the supply voltage, the more back EMF you can handle, which is possibly why the industry is moving from the 200-400 volt batteries to an 800 volt battery.

Torque changes depending on where it is measured in the powertrain. Torque to the wheels can be defined as the total torque and is the final measurement. Torque originates from the internal combustion engine or the three-phase motor in an electric vehicle. Torque from the power source is multiplied by the total gear ratio to achieve total torque at the wheels. Let’s compare torque numbers from a Ford Bronco with a four-cylinder engine to a Chevy Bolt.

Torque changes depending on where it is measured in the powertrain. Torque to the wheels can be defined as the total torque and is the final measurement. Torque originates from the internal combustion engine or the three-phase motor in an electric vehicle. Torque from the power source is multiplied by the total gear ratio to achieve total torque at the wheels. Let’s compare torque numbers from a Ford Bronco with a four-cylinder engine to a Chevy Bolt.

- Ford Bronco engine torque: 315 lb. ft.

- First gear ratio: 6.58:1

- Transfer case low range ratio: 3.06

- Final drive ratio: 4.7:1

- Formula for total gear ratio: 6.58 x 3.06 x 4.71 =94.6:1

To achieve total torque, we simply multiply the torque from the power source by the total gear ratio.

315 x 94.6 = 29,799 pound-feet of torque.

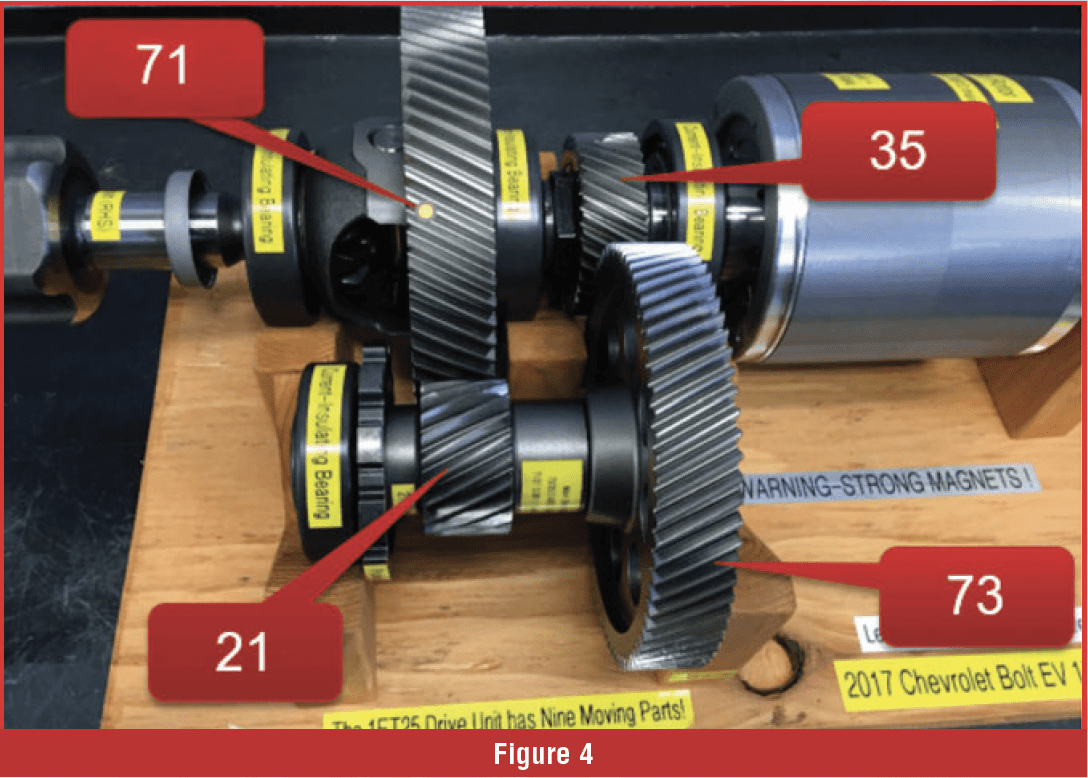

The total torque to the wheels in first gear, low range, is incredible and could climb a very steep grade; however, the limiting factor here is speed. You cannot travel down the road in first gear, low range, which is why it has high range and a seven-speed transmission. Now, let’s turn our attention to an electric vehicle; the Chevy Bolt. The torque originates from the three-phase motor, which is rated at 266 pound-feet of torque at 350 volts.  The total gear ratio is obtained in the transaxle. The total gear ratio, as explained earlier, is found by multiplying all the gear ratios involved. A gear ratio is determined by dividing the driven gear by the drive gear. We will look at the gear layout in a Chevy Bolt transaxle and determine each gear ratio individually (Figure 4).

The total gear ratio is obtained in the transaxle. The total gear ratio, as explained earlier, is found by multiplying all the gear ratios involved. A gear ratio is determined by dividing the driven gear by the drive gear. We will look at the gear layout in a Chevy Bolt transaxle and determine each gear ratio individually (Figure 4).

Using the formula, the driven gear divided by the drive gear, we can determine each gear ratio individually and then multiply all the gear ratios to determine the total gear ratio.

73 ÷35 = 2.0857

71 ÷ 21 = 3.3809

2.0857 x 3.3809 = 7.05 TGR

To determine the total torque to the wheels, we can multiply the torque from the electric motor by the total gear ratio.

266 x 7.05 = 1,875.3 pound-feet of torque to the wheels.

Let’s review the difference between the Ford Bronco and the Chevy Bolt EV. The Ford Bronco produced 29,799 pound-feet of torque in first gear, low range, but is limited to approximately 15 mph. The only way to change the total torque and speed in the Bronco is to change the range in the transfer case and shift to a higher gear in the transmission. The Bronco is constantly changing the total torque output depending on the gear ratio selected. The Chevy Bolt EV has a single gear ratio that remains constant. The Chevy Bolt EV’s output is 1,875 pound-feet of torque from the time the electric motor starts to rotate until approximately 6,000 RPMs. Then the torque gradually starts to diminish until the motor reaches a max RPM of 8,810. Another example of an EV is the Tesla Model 3, which features a single-speed gearbox with a total gear ratio of 9:1, achieving a top speed of 162 mph. Why does the Tesla Model 3 have a higher speed rating than the Chevy Bolt, especially given that the Tesla Model 3 has a lower total gear ratio? Motor speed is the answer.  The Chevy Bolt limits the speed of the electric motor to 8,810 RPM, and the Model 3 limits motor speed to 16,000 RPM. The Tesla S Plaid model allows the motor to reach approximately 20,000 RPMs. The Tesla S Plaid model has a top speed of approximately 200 mph, with a single-speed transmission.

The Chevy Bolt limits the speed of the electric motor to 8,810 RPM, and the Model 3 limits motor speed to 16,000 RPM. The Tesla S Plaid model allows the motor to reach approximately 20,000 RPMs. The Tesla S Plaid model has a top speed of approximately 200 mph, with a single-speed transmission.

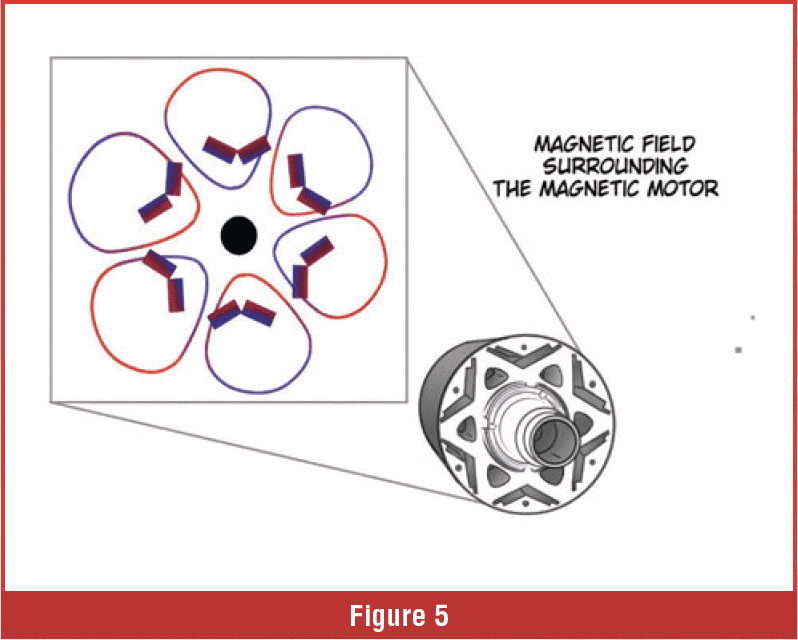

A limiting factor in electric motor RPM is bearing and rotor failure. We can solve the bearing problem by switching to high-speed bearings, but the rotor must also be redesigned for high speeds. Permanent magnet motors have embedded magnets into the electrical steels of the rotor. High RPM puts a significant amount of centrifugal force on the magnets, putting pressure on the electrical steels. These embedded magnets tend to break through the electrical steels at higher RPMs, causing the rotor to basically y apart. The rotors were redesigned to change the angle of the magnets and install them a little deeper below the surface (Figure 5).  Tesla put a carbon wrap on the outside of the rotor to keep the magnets from breaking through on the S Plaid model (Figure 6). Each manufacturer publishes the electric motor RPM limit, kind of like redline specs for a gasoline engine. Here are a few examples of electric motor RPM limits:

Tesla put a carbon wrap on the outside of the rotor to keep the magnets from breaking through on the S Plaid model (Figure 6). Each manufacturer publishes the electric motor RPM limit, kind of like redline specs for a gasoline engine. Here are a few examples of electric motor RPM limits:

- Chevy Bolt -8,810 RPM

- Nissan Leaf -10,500 RPM

- Tesla Model 3- 16,000 RPM

- Tesla Model S Plaid -20,000 RPM

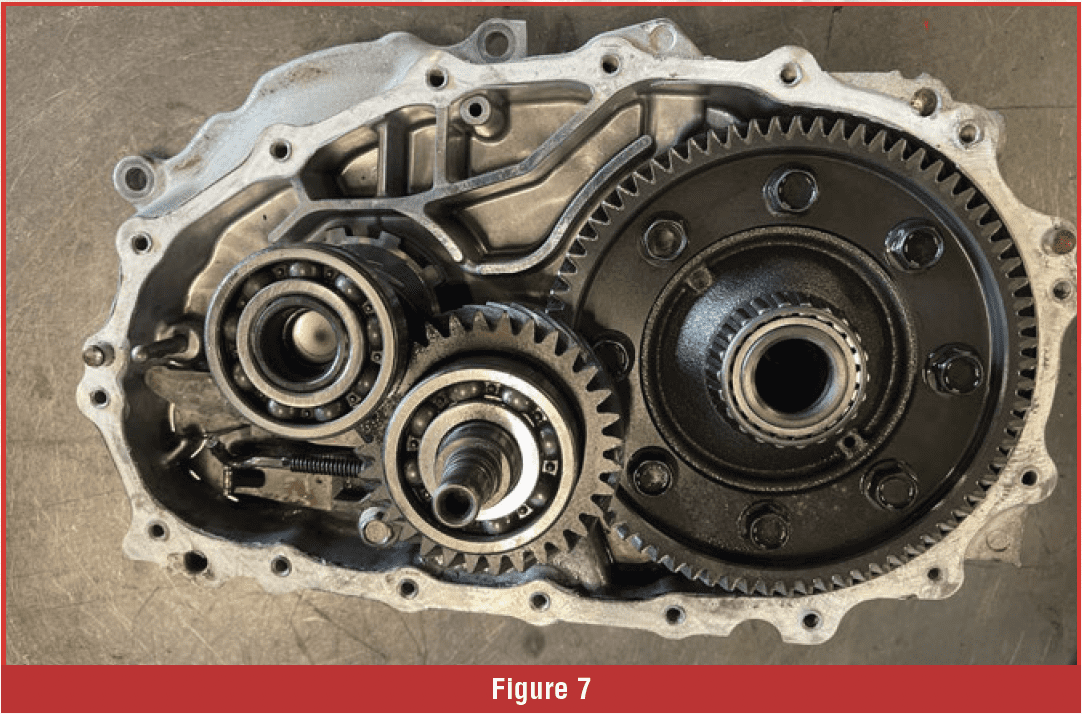

Each manufacturer has slightly different total gear ratios, and the gearbox designs are not all the same. Let’s look at a gearbox from a Nissan Leaf (Figure 7). The motor gear is small and has 17 teeth. The main shaft’s driven gear has 32 teeth, which makes the first gear ratio 1.88:1. The main shaft drive gear has 17 teeth, and the differential ring gear has 74 teeth, so the second gear ratio is 4.35. To calculate the total gear ratio, we must multiply the gear ratios together.

Each manufacturer has slightly different total gear ratios, and the gearbox designs are not all the same. Let’s look at a gearbox from a Nissan Leaf (Figure 7). The motor gear is small and has 17 teeth. The main shaft’s driven gear has 32 teeth, which makes the first gear ratio 1.88:1. The main shaft drive gear has 17 teeth, and the differential ring gear has 74 teeth, so the second gear ratio is 4.35. To calculate the total gear ratio, we must multiply the gear ratios together.

1.88 x 4.35 = 8.192

The Nissan Leaf has a single ratio of 8.192:1. This is a very simple gear train with no planetary gears, wet clutches, one-way clutches, synchronizers or any sort of shifting mechanism. This simplified design with few parts is shared by most electric vehicles.

We’ll look at EV gearbox failures and the features and designs of hybrid vehicles in future articles. Both EV and hybrid vehicles have failures that you in the transmission-repair business can handle, and make profit from. Think of future technologies as… just different.

About the Author: Jerry Stewart develops technical training at AVI and teaches automotive technology at Highlands College in Montana. He bridges the gap between industry and academia, equipping students with real-world skills for careers in the transportation field.