Aus-Tex Transmission is in Round Rock, Texas, about 10 miles north of Austin. So why Aus-Tex, if it isn’t in Austin? Because this is a new location; the old shop was in Austin. They moved to the new shop in October of 2016.

Okay, moving to a newer, larger shop isn’t uncommon; a lot of shop owners move once their business outgrows the original location. But 10 miles is a long way to move… even in Texas (where, you know, everything’s bigger). Generally, a move like that means starting over. Why so far?

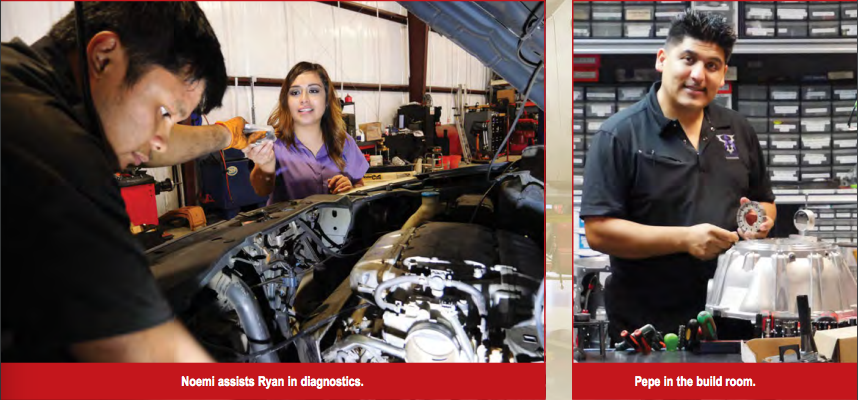

Turns out the old shop was in a not-so-nice neighborhood, and it was affecting their business. “We had a really hard time getting people to come work there,” says Aus-Tex owner Pepe Torres. “Good potential employees would be scheduled for an interview. They’d look at the shop, they couldn’t find a parking spot, and they’d just keep going and never come back.”

That’s not a problem with their new shop: a build-to-suit property in a nice neighborhood. The new shop is 10,600 square feet; about three times the size of the old building.

“We drew up the plans for the building we wanted — the offices, the waiting room, the transmission building room — and we signed a 5-year lease-to-buy contract. At the end of five years I have to buy the building.”

The move also puts Pepe closer to home: “We’re just seven minutes from home now,” he explains. And that makes a lot of things easier for him and his wife, Teresa, who manages the shop’s business and marketing operations.

The move wasn’t easy for them. “There were many expenses and setting up the shop was very costly,” he says. But with hard work and some valuable business practices, Aus-Tex is starting to climb back and become successful again.

AN EARLY START

“I came from very humble beginnings,” explains Pepe. “I grew up as a farm boy in Mexico. My parents moved here when I was a kid. They taught me to work hard and always respect others.

“I got into the auto repair business when I was 15 years old. My first real job was at Pep Boys as a ‘tire buster’; I was doing tires and oil changes. I had to lie about my age because I wasn’t 18 yet.

“I got into the auto repair business when I was 15 years old. My first real job was at Pep Boys as a ‘tire buster’; I was doing tires and oil changes. I had to lie about my age because I wasn’t 18 yet.

“They moved me up to ‘flag hour’ (flat rate) within a year, while I was still a minor. Then I took at job at a GM dealership for about four years.

“I became an ASE Master Technician when I was 22 years old. The only test I had a little problem with — but I still passed it! — was the transmission test. I’d never really been into a transmission before.

“I knew how to R&R a transmission and I’d had a 4L60 pump out when I worked for the dealer. But I didn’t really know what was going on inside. I passed the test based on simple logic.

“I got into the transmission work in 2004. I made one of the biggest mistakes of my life and bought a failed, bad-reputation, bad-reviewed transmission shop. That was how I got into transmissions full time. I was misled, but was able to make the best out of a bad situation.”

So how was Pepe able to create a successful transmission business with almost no transmission experience? In the beginning he was self-taught and he learned a lot of what he needed by trial and error.

Then he found ATRA: “I learned about the ATRA seminars and I started going to them. I started reading GEARS and reading on line, learning more and more about transmissions.

“The first time I went to an ATRA seminar, I barely had enough money for gas. I didn’t want to be late so I drove to Houston the night before and stayed in the parking lot ’cause I couldn’t afford a hotel. It was freezing; I had to start my car every few hours just to warm up.

“It was an experience I’ll never forget, but it was my first ATRA seminar and I loved it. I grasped as much information as I could. It was the first time I heard about ‘shift adapts.’

“I always sit at the front of the class, asking all the questions I can; whether it’s at a seminar or at Expo, it doesn’t matter. I’m always asking questions.”

TRANSMISSIONS AND DIESEL REPAIRS

When Pepe bought Aus-Tex, it was a transmission-only shop. “When I first opened the shop I didn’t have a lot of experience in transmissions. So I knew I needed a backup plan: something else that was certain to bring in money.

“I started working on a couple diesel trucks, because no one in Austin wanted to work on them. I knew a bit about Duramax from when I worked at the dealer.

“So I started working on diesels, and two years later I took the L2 ASE certification for advanced diesel performance. I actually learned from the test and I got really interested in them.

“I started telling people we do diesel work and I hung a sign that said ‘diesel specialist.’ We started getting in a lot more work. Today about 50% of our revenue is from diesel repair.” And, of course, their diesel work often leads to transmission repairs.

One thing he’s discovered is that a lot of those transmissions behind diesel engines are being torn up because the vehicle’s owner installed a “tuner” to alter the engine’s power curve. But that additional power can quickly destroy a transmission that would have been fine behind a factory-tuned diesel engine.

That experience is why Pepe will be at this year’s Expo, to present a program for the technical track, tentatively titled Blame It on the Tuner. In it, he’ll discuss what he’s learned about building transmissions that can keep up with that additional power. “It’s my way of giving back to the Association,” he says.

Aus-Tex handles all transmission repairs in house. The only thing they avoid repairing themselves are transfer cases. “I don’t like messing with transfer cases myself because I always end up spending too much on parts,” explains Pepe.

“Even if I have to sell a transfer case for just about my cost, I’m not going to build it; I’ll sell a reman transfer case every time.”

PROCESSES AND PROCEDURES

The importance of creating a business model built on specific processes and procedures should be a familiar one to regular GEARS readers. And at Aus-Tex, those processes and procedures have become nearly an art form.

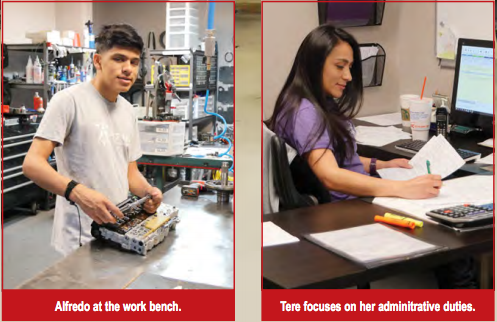

According to Pepe, every employee has a checklist of procedures to follow for every job he or she does. And they have to initial each step to verify that they’ve performed them.

“The transmission rebuilder helper has a list that says ‘wash the case in the parts washer,’ ‘clean the pan,’ ‘make sure the magnet’s there.’ He knows exactly what’s expected of him, and he knows he’s responsible for doing each step properly,” says Pepe.

And not just the technicians; even the service advisors have a checklists to follow. “The services writers’ checklist says they have to greet the customer and they have to have a conversation with the customer that has nothing to do with their cars,” explains Pepe. “It can be about the weather or how their kids are doing.” Something to help build a personal relationship with them.

“Then they have to log the vehicle in, record the customer’s original complaint, and determine how the customer’s going to get home or to work… whether they need a ride or have transportation planned.

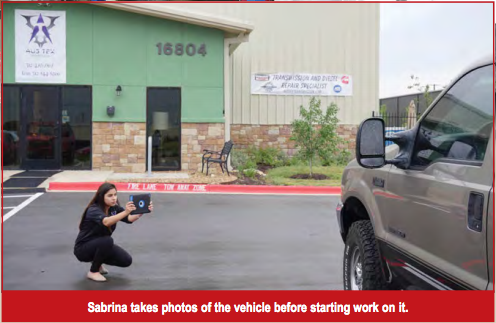

“Part of logging the vehicle involves taking pictures of the car. We take a picture from every corner, to record any dents or scratches, so there aren’t any questions about whether they were there before the car came in. And they take a picture of the odometer or hour meter.”

And all of those photos are kept in the shop’s files, just in case a problem comes up later on.

And all of those photos are kept in the shop’s files, just in case a problem comes up later on.

“They also have to dispatch the job to the right technician and prepare estimates for me or Teresa to call the customer.”

“So everyone has a list of procedures to follow and initial. And it’s worked real well for us; we’ve perfected it over the years, and we keep adding and modifying the checklist about every year.”

The checklist is also a terrific help for training new employees. “New employees don’t know what to do. You give them a list and they know what’s expected of them.”

Of course, not everyone follows procedures exactly as they’ve been listed. That can lead to problems for the shop and the employee. “People who don’t like to follow directions often skip steps… and that’s when mistakes happen.

“If there’s a mistake, we go back to the checklist and ask, ‘Why didn’t you follow the steps? You’ve made this mistake three times; you’ve skipped this step three times.’ And that provides us with documentation when we have to let someone go for not following procedures.

“Yeah, we have some employee turnover, but you can’t afford to have people who aren’t doing the job right when you’re offering a 3-year, 100,000-mile warranty.” And, thanks to those checklists, everyone in the shop knows what it means to do the job right.

NEW EMPLOYEES

While many successful shops have a number of longtime employees, Aus-Tex is mostly staffed by new people. That’s because Pepe doesn’t believe in keeping an employee who won’t conform to his business model. He wants people who’ll do a good job and who’ll follow his procedures. If they can’t do that, he’ll send them packing.

“We open at eight o’clock; that’s when customers start coming in,” explains Pepe. “I need my guys here to road test cars or take customers home. If they can’t meet my requirements, I don’t want them here.”

Fair enough, but a lot of shops deal with employees who maybe aren’t exactly what they were hoping for. They have to, because they just can’t find qualified help to replace them. Where does Pepe find new technicians?

“I’ll put ads on social media, Craig’s List, and even Monster.com, and let people know I’m looking. I’ll ask them to send me a text message; that shows me that they have at least some familiarity with computers.

“Once I get a few people interested, I’ll run online checks. I’ll check their social media pages to see what they post. If they show me something having to do with car repair, I know they have some pride in what they do; they’ll get an interview.”

Pepe also has a page on his web site — AusTexTransmission.com — for people who’d like to work there. “We get people who fill out the online application. We’ll go through those applications and run a basic background check to see if the applicant might be a good fit. If so, I’ll give him an interview.”

Pepe’s always on the lookout for a strong candidate: “I’ll be talking to someone at a diner or at a store, and we’ll make a connection. If they seem interesting, I’ll look into them further.

Pepe’s always on the lookout for a strong candidate: “I’ll be talking to someone at a diner or at a store, and we’ll make a connection. If they seem interesting, I’ll look into them further.

“I also build relationships with technicians in other shops — the guy I hired to handle a reflash or something like that. They get to know me and, one day, when they’re looking to move on, they’ll contact me.”

According to Pepe, looking for new talent is a full-time job. It isn’t something you can do just when you have an opening. You have to keep an eye out all the time or a terrific employee might slip through your fingers.

It must be working, because even with a recent move, Aus-Tex Transmission is well staffed and doing great. We look forward to hearing from him at this year’s Expo.