The RAM ProMaster is a light to medium duty van used for everything from local delivery to short-haul transport. RAM produces the 1500, 2500, and 3500 versions based on cargo handling capacities. The gas-powered version uses the 3.6L motor with the 62TE transmission. From 2014 to 2017, they produced these vehicles equipped with a 3.0L diesel motor and an automatically shifted manual transmission called the M40MTA.

The M40MTA is a manual transaxle that uses a single, dry disc clutch mounted to a dual-mass flywheel. A bolt-on Hydromechanical unit, using high-pressure fluid, controls shifting and clutch operations. A stand-alone TCM controls the Hydromechanical unit.

We introduced the unit and its control system in the January 2022 edition of GEARS magazine. We learned that the Hydromechanical unit operates at pressures up to 1,100 psi! As a result, you MUST perform the depressurization procedure and ensure the system is safe before working on the system or individual components; otherwise, serious injury and/or damage to the vehicle will occur.

In this article, we’ll take a look at patterned failures and issues these transmissions are experiencing. So, let’s dig in and see what’s happening with these units!

IT’S A MANUAL TRANSMISSION; WHAT COULD GO WRONG?

The M40MTA transmission logged hundreds of thousands of miles around the world. Only recently, they are showing up more frequently in shops with issues. One of the most common complaints is a no-move condition. Keeping in mind that this is nothing more than your typical manual transmission with a bolt-on control assembly, basic diagnostics take us to the most likely culprit, which would be the clutch assembly first. However, before jumping to conclusions, several different no-move modes can occur:

- It shifts into neutral (computer commanded).

- It goes to neutral on the highway (pops out of gear).

- It’s stuck in neutral (cannot select any range, computer commanded).

- The transmission won’t shift.

Note that all of these complaints can be caused by the computer operating strategy forcing neutral because it can’t select the next gear, or the shift position sensors give the TCM feedback that the unit is in another gear. Also, component failures on the Hydromechanical unit or issues internal to the transmission may be the culprit. So, let’s take a closer look into actual failures logged by this unit.

SOLENOID RELATED FAILURES

SOLENOID RELATED FAILURES

The Hydromechanical unit has four solenoids that control shifting and clutch operation. These solenoids are linear, pulse width modulated, and operate in a high-pressure environment (500 to 1,100 psi). As mentioned earlier in this article, follow the depressurization procedure before inspecting or servicing these solenoids. While the solenoids operate valves that modulate control oil, it is not common for the solenoid to electrically or mechanically fail.

However, O-rings separate the circuits the solenoid valve controls (figure 1). These O-rings flatten and fail over time and cause shift errors and no move conditions.

INTERNAL UNIT ISSUES

As these units age, internal issues become more likely, especially if the vehicle spends most of its time in urban driving conditions. Before removing the unit, verify that the clutch, the Hydromechanical unit, and related components are in good operating condition.

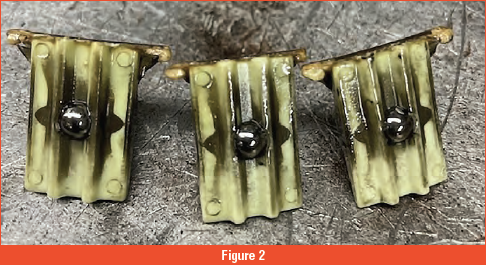

In this case, we removed and then disassembled the transmission. At first glance, nothing obvious had failed. However, looking closer, we discovered significant wear on the slider dogs (figure 2).

Like in conventional manual transmissions, the dogs keep the transmission in the selected gear. Wear to this extent would cause the unit to drop out of gear.

Worn shift forks are also a common problem. Moderate to significant damage can occur (figures 3a & 3b). The transmission programming is designed to attempt a shift into a specific gear twice before it skips to the next gear. A complaint of intermittent no-shift into a specific range often indicates that shift fork wear may be present.

Always inspect the shift sleeve for damage, given the amount of wear on the shift forks. Replace the entire synchronizer assembly if considerable wear is present. In this case, the shift sleeves did not suffer damage. Note that minor damage can be cleaned up. Ensure that the shift sleeve surfaces where the forks ride are free of rough spots and transferred metal.

THE FIX!

Part availability can be an issue with this unit, as it is with most manual transmissions now. Contact your local Mopar dealership before moving too much further with a repair. Core units are available in limited supply in the aftermarket. The complete unit is available for approximately $9,200 installed from Mopar with a 3-year, 36,000-mile warranty. The Hydromechanical unit lists for about $1,000 out the door.

Note that if the bulk of the damage that occurred is in the shift fork wear, you can service them by brazing metal to the fork surfaces and finishing them smooth. This is an acceptable repair to restore the original dimensions and place them back into service. It will also save you significant time and money in most cases. If you cannot perform this, contact a local welder or machine shop.

Knowing what can and does fail in a unit makes quick work out of a difficult situation. You can make the right call from diagnosis to delivery with this information!

‘Till next time, see ya!