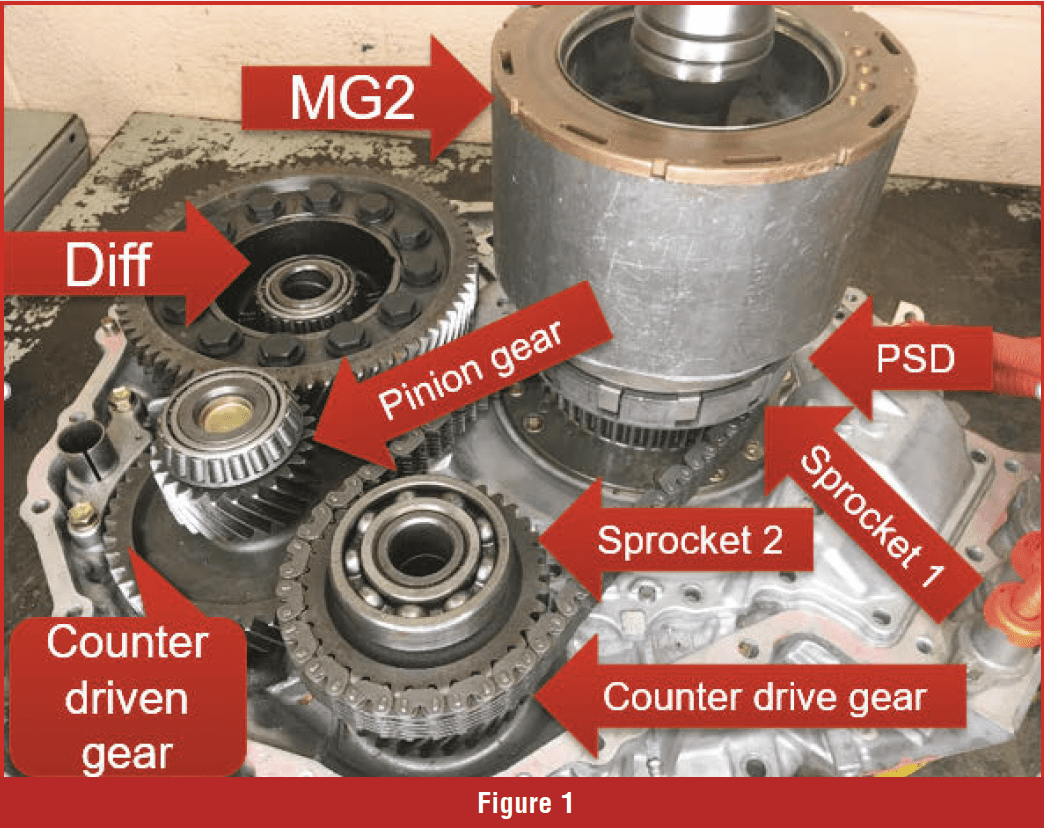

Last time we visited, we talked about an EV’s gear train and how it interacted with the electric motor. Most EV gear trains employ a one-speed transmission. We discovered that the faster an electric motor turns, the more back EMF it produces. The back EMF works against the supply voltage to the motor, which reduces its efficiency. In this article, we’ll turn our attention toward hybrid gear trains and their interaction with the internal combustion engine (ICE). We will start with a first-generation Prius transaxle. The first Gen Prius transaxle was a P111 transaxle that housed two electric motors, MG1, MG2, a power split device (PSD), chain, and sprockets, a counter drive gear, a counter driven gear, a pinion gear, and a differential. MG1 and MG2 were mounted on an inline axis. (Figure 1).

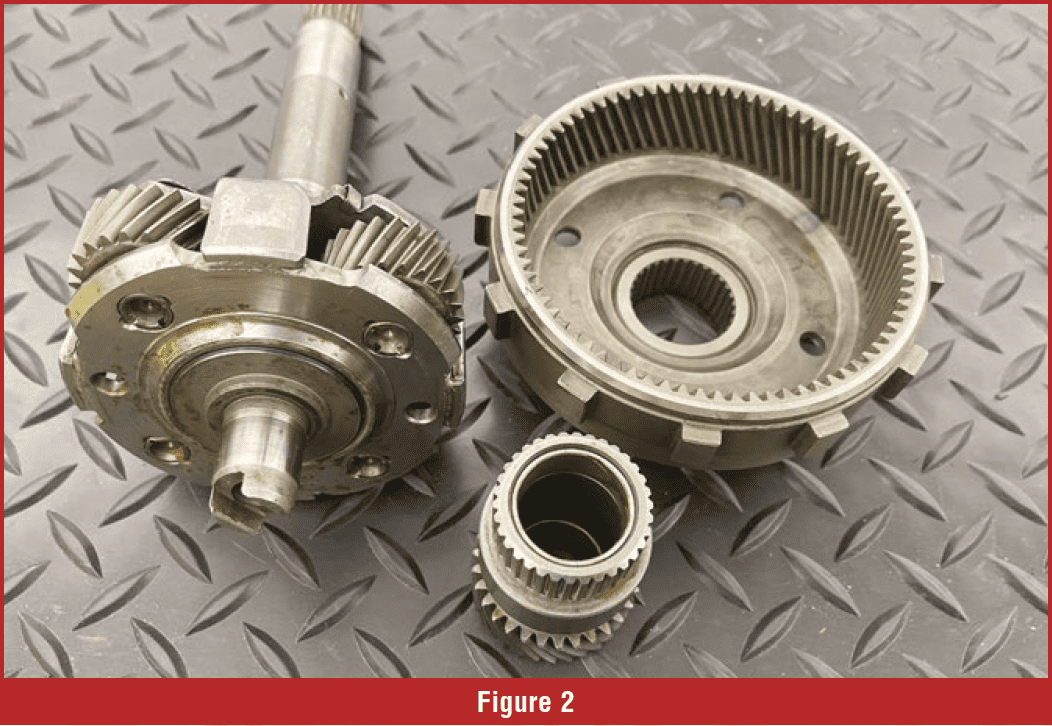

The P111 is listed as a CVT, which might lead you to believe it has two variable-diameter pulleys with a belt, but it does not. The P111 does not incorporate any wet clutches, bands, or one-way clutches either. In fact, the total gear ratio is set and never changes. The gear train provides a fixed gear ratio at 3.89:1. What changes is the torque input to the gear train. The two torque inputs are the ICE and MG2.  The P111 does use one traditional part found in automatic transmissions, which is a planetary gear set known as the power split device. The power split device can be seen in Figure 2.

The P111 does use one traditional part found in automatic transmissions, which is a planetary gear set known as the power split device. The power split device can be seen in Figure 2.

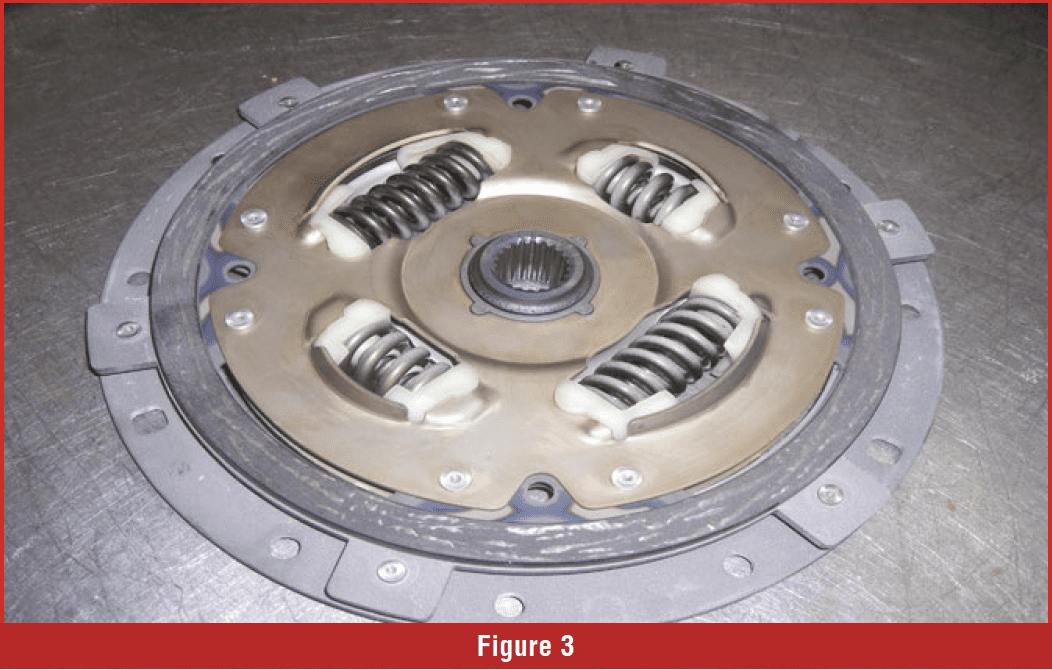

The PSD sits between MG1 and MG2. The PSD connects all three major parts, which are the ICE, MG1, and MG2. The PSD has three parts: the planet carrier, sun gear, and internal ring gear. The planet carrier incorporates a shaft that indexes into an input clutch damper. The input clutch damper is bolted to the flywheel, so the planet carrier is connected to the ICE. (Figure 3).

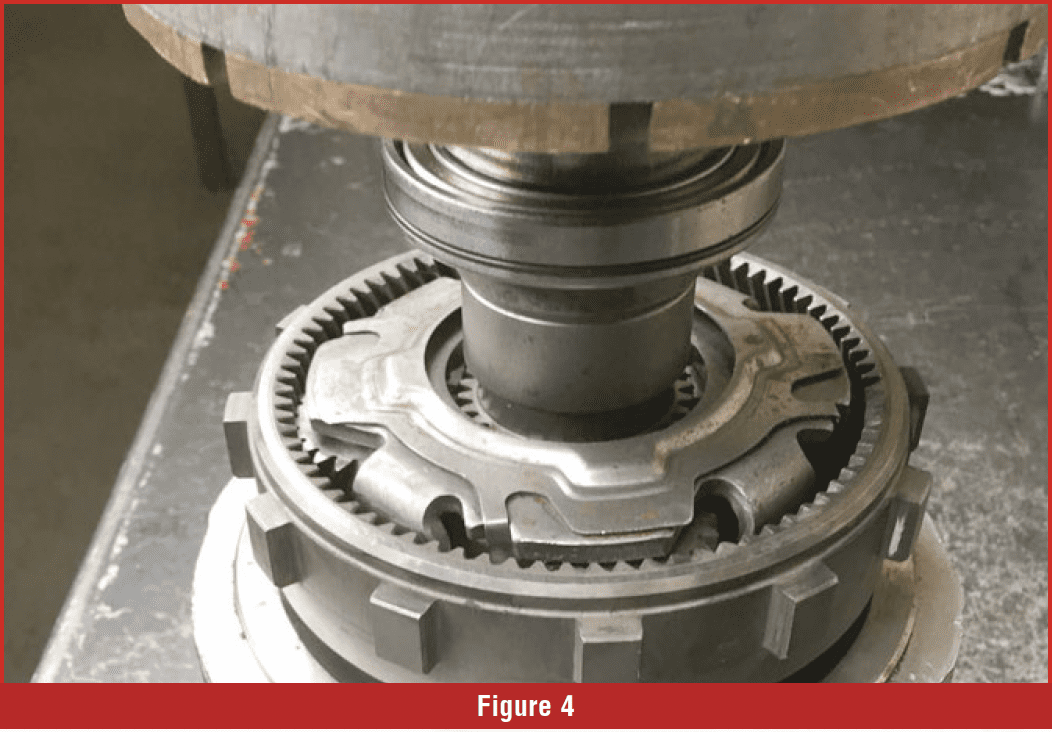

The sun gear of the PSD is connected to MG1, and the internal ring gear of the PSD is connected to MG2 (Figure 4). MG1 starts the ICE by applying torque to the sun gear. MG1 rotates the sun gear, which rotates the planet carrier. The internal ring gear is held by MG2. This creates a 3.6:1 gear ratio through the PSD while cranking the ICE. MG1 rotates at approximately 3600 RPM when cranking the ICE to create a 1000 RPM cranking speed of the ICE. Most engines crank around 250 RPM, so 1000 RPMs is quite a bit faster than the traditional 12-volt starter-equipped vehicles.

Once the ICE starts, it can split its torque between MG1 and the gear train. The Ice spins MG1 to generate electrical power that can be used to charge the high-voltage battery and supply energy for MG2. MG1’s main purpose is to start the engine and become a generator when rotated by the engine to provide power.  MG1 does not contribute torque to the gear train on this model transaxle. MG2 is connected to the internal ring gear and can directly drive the vehicle in pure electric mode, or it can receive torque from the ICE through the PSD. The torque can vary from the ICE and MG2, but both torque inputs join at the internal gear with the torque from MG2, the torque travels through the gear train at a fixed ratio of 3.89:1. MG2 also becomes a generator during deceleration and braking events.

MG1 does not contribute torque to the gear train on this model transaxle. MG2 is connected to the internal ring gear and can directly drive the vehicle in pure electric mode, or it can receive torque from the ICE through the PSD. The torque can vary from the ICE and MG2, but both torque inputs join at the internal gear with the torque from MG2, the torque travels through the gear train at a fixed ratio of 3.89:1. MG2 also becomes a generator during deceleration and braking events.

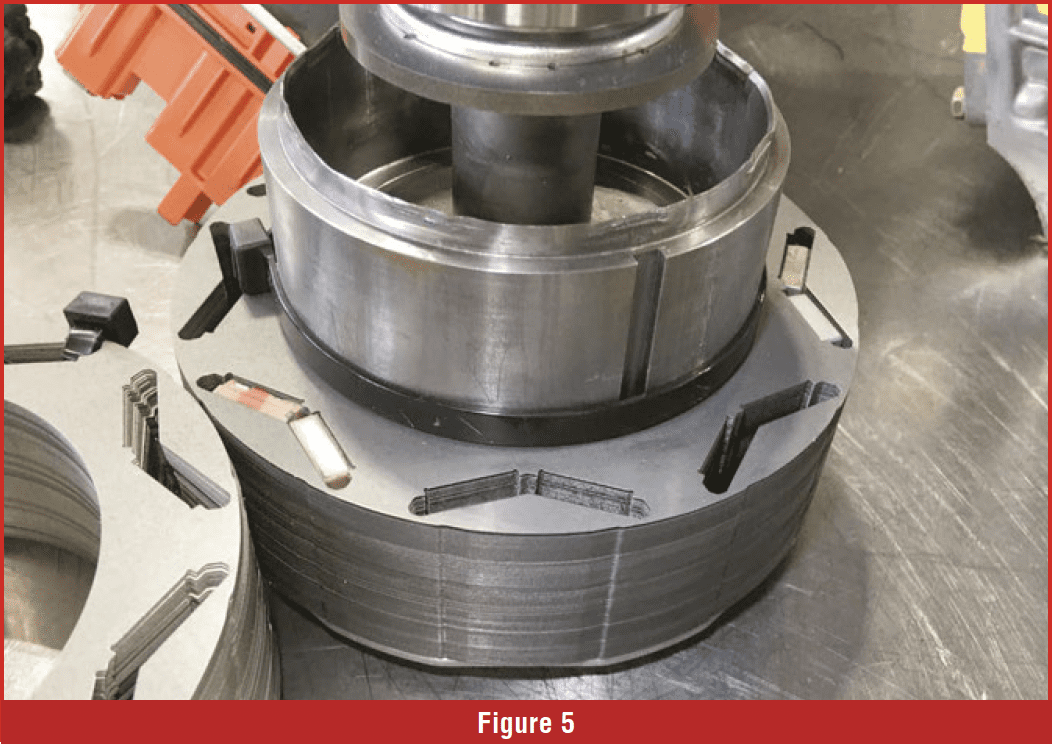

When driving in electric mode only with the ICE shut off, MG2 sends torque to the gear train while MG1 freewheels in reverse rotation. MG1 does not generate any power when it is freewheeling in reverse rotation. Due to the gear ratio and planetary action of the PSD, MG1 spins in reverse rotation 2.6 times faster than MG2. This limits our speed in electric drive only because MG1 has a 6500 RPM limit in this early model transaxle. Spinning MG1 faster than 6500 RPMs can damage the motor. The rotor of MG1 has magnets located internally. The magnets sit fairly close to the outside or edge of the rotor. As the rotor spins, the magnets are subject to centrifugal force at speeds above 6500 RPMs. The magnets may break through the rotor and destroy the motor. (Figure 5)

The magnets sit fairly close to the outside or edge of the rotor. As the rotor spins, the magnets are subject to centrifugal force at speeds above 6500 RPMs. The magnets may break through the rotor and destroy the motor. (Figure 5)

MG2 in the first Gen is a very large motor and outputs 258 pound-feet of torque. Torque to the wheels in electric mode can be calculated by multiplying MG2 torque times the total gear ratio of 3.89:1. 258 x 3.89 = 1003 pound-feet of torque to the wheels in electric drive mode. In hybrid drive mode, the ICE can contribute its torque as well, which will raise the overall torque to the wheels. As we cover the next generations of Prius, we will notice that the torque in electric mode continually increases.

Gen 2 transaxle uses a P112 transaxle, which is very similar to the P111. Inside the P112, MG1 & MG2 retained the inline axis mounting and retained the chain drive, but changed the sprocket ratio on the chain drive. The sprocket ratio on Gen 2 is .97:1 compared to Gen 1 at .92:1. MG1 was redesigned and now has an RPM limit of 10,000 RPM versus 6500 RPM of the P111. MG2 torque was increased from 258 to 295 pound-feet of torque. The total gear ratio changed from 3.89:1 to 4.1:1. We can determine the torque to the wheels in electric drive mode by multiplying MG2 output times the total gear ratio. 4.1 x 295 = 1209.5 pound-feet of torque compared to 1003 pound-feet of torque on Gen 1. MG2 powers the gear train in electric drive mode but also becomes a generator during deceleration and braking events, as it did in Gen 1.

Gen 2 transaxle uses a P112 transaxle, which is very similar to the P111. Inside the P112, MG1 & MG2 retained the inline axis mounting and retained the chain drive, but changed the sprocket ratio on the chain drive. The sprocket ratio on Gen 2 is .97:1 compared to Gen 1 at .92:1. MG1 was redesigned and now has an RPM limit of 10,000 RPM versus 6500 RPM of the P111. MG2 torque was increased from 258 to 295 pound-feet of torque. The total gear ratio changed from 3.89:1 to 4.1:1. We can determine the torque to the wheels in electric drive mode by multiplying MG2 output times the total gear ratio. 4.1 x 295 = 1209.5 pound-feet of torque compared to 1003 pound-feet of torque on Gen 1. MG2 powers the gear train in electric drive mode but also becomes a generator during deceleration and braking events, as it did in Gen 1.  We can determine MG2’s mode of operation by watching scan data. When scan data indicates MG2 is positive RPM and positive torque, MG2 is in motor mode, applying torque to the gear train. When MG2 shows positive RPM and negative torque, it is in generator mode. When MG2 shows negative RPM, it is providing reverse. The gear train does not provide a reverse gear, so reverse is controlled by the direction of rotation of MG2.

We can determine MG2’s mode of operation by watching scan data. When scan data indicates MG2 is positive RPM and positive torque, MG2 is in motor mode, applying torque to the gear train. When MG2 shows positive RPM and negative torque, it is in generator mode. When MG2 shows negative RPM, it is providing reverse. The gear train does not provide a reverse gear, so reverse is controlled by the direction of rotation of MG2.

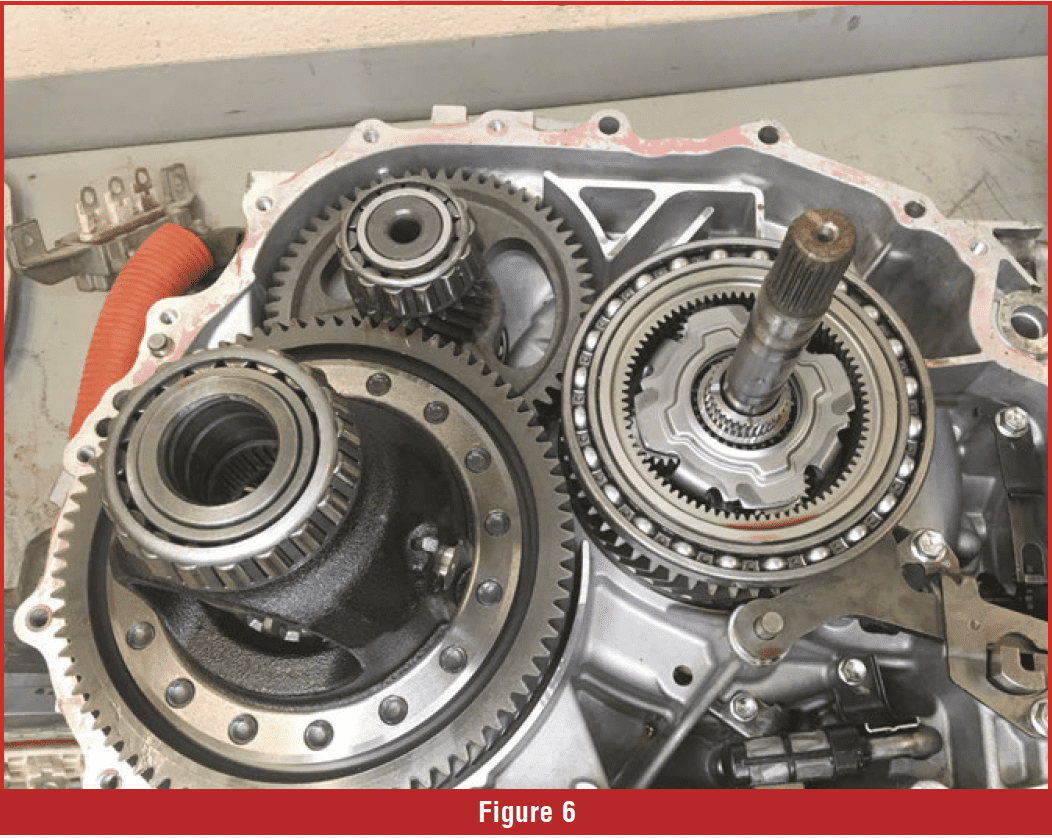

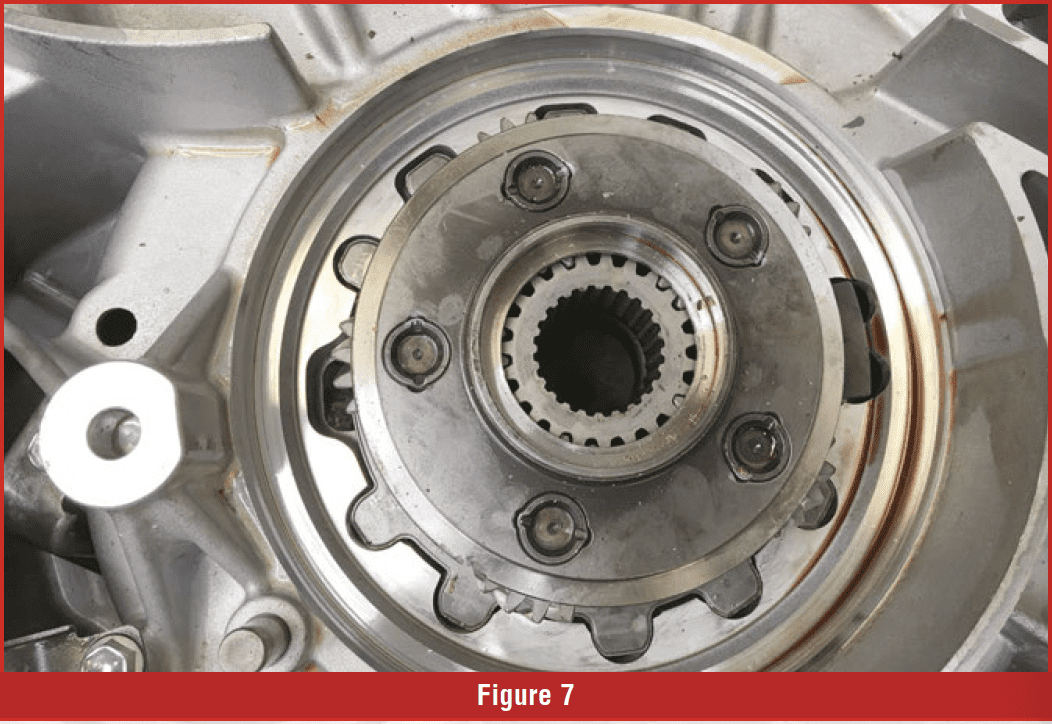

Gen 3 transaxle MG1 & MG2 retained the inline axis, but the gear train changed drastically. The chain drive was eliminated in favor of a gear-to-gear design. The transaxle also retained the PSD unit (Figure 6). MG1 speed rating was increased from 10,000 RPMs on Gen 2 to 13,500 RPMs on Gen 3. MG2 was downsized and now only outputs 153 pound feet of torque, versus Gen 2, which outputted 295 pound feet of torque. It would appear the torque of MG2 is going the wrong direction; however, the third Gen adds another planetary gear set to the gear train.  (Figure 7) The sun gear of the new planetary set is connected to MG2. The planet carrier is stationary and indexed into the case. The internal ring gear has a double set of internal teeth, one set that engages the stationary planet carrier and another set that engages the power split device. The internal ring gear also has an external gear that transmits power to the gear train. The newly added planetary gear set provides a gear ratio or torque increase of 2.63:1 to MG2. To obtain the total torque output of MG2, we will need to take the torque output of MG2 and multiply it by the gear ratio of the added planet (153 x 2.63 = 403 poundfeet of torque). MG2 on the previous model outputted 295 pound-feet of torque compared to 403 pound-feet on the Gen 3 model. That is an increase in overall torque output with a smaller output electric motor.

(Figure 7) The sun gear of the new planetary set is connected to MG2. The planet carrier is stationary and indexed into the case. The internal ring gear has a double set of internal teeth, one set that engages the stationary planet carrier and another set that engages the power split device. The internal ring gear also has an external gear that transmits power to the gear train. The newly added planetary gear set provides a gear ratio or torque increase of 2.63:1 to MG2. To obtain the total torque output of MG2, we will need to take the torque output of MG2 and multiply it by the gear ratio of the added planet (153 x 2.63 = 403 poundfeet of torque). MG2 on the previous model outputted 295 pound-feet of torque compared to 403 pound-feet on the Gen 3 model. That is an increase in overall torque output with a smaller output electric motor.  Smaller motors with fewer windings and a smaller rotor magnet create less back EMF, as discussed in the previous article, which also increases the electrical efficiency of the motor. Due to the added planet, the total gear ratio has changed in the Gen 3 design. To obtain the total gear ratio, we must multiply all the gear ratios involved. There are three gear ratios involved in calculating the total gear ratio. The counter gear and counter-driven gear create a 1.019:1 gear ratio. The final drive creates a 3.208:1 gear ratio, and the newly added planetary gear creates a 2.63:1 gear ratio. When we do the math, 1.019 x 3.208 x 2.63 =8.57:1 total gear ratio. Let’s review the total gear ratios on all three generations. Gen 1-3.89:1, Gen 2 4.1:1, and Gen 3 8.57:1. As the generations advanced, the total gear ratios got lower, which helps increase the overall torque output.

Smaller motors with fewer windings and a smaller rotor magnet create less back EMF, as discussed in the previous article, which also increases the electrical efficiency of the motor. Due to the added planet, the total gear ratio has changed in the Gen 3 design. To obtain the total gear ratio, we must multiply all the gear ratios involved. There are three gear ratios involved in calculating the total gear ratio. The counter gear and counter-driven gear create a 1.019:1 gear ratio. The final drive creates a 3.208:1 gear ratio, and the newly added planetary gear creates a 2.63:1 gear ratio. When we do the math, 1.019 x 3.208 x 2.63 =8.57:1 total gear ratio. Let’s review the total gear ratios on all three generations. Gen 1-3.89:1, Gen 2 4.1:1, and Gen 3 8.57:1. As the generations advanced, the total gear ratios got lower, which helps increase the overall torque output.

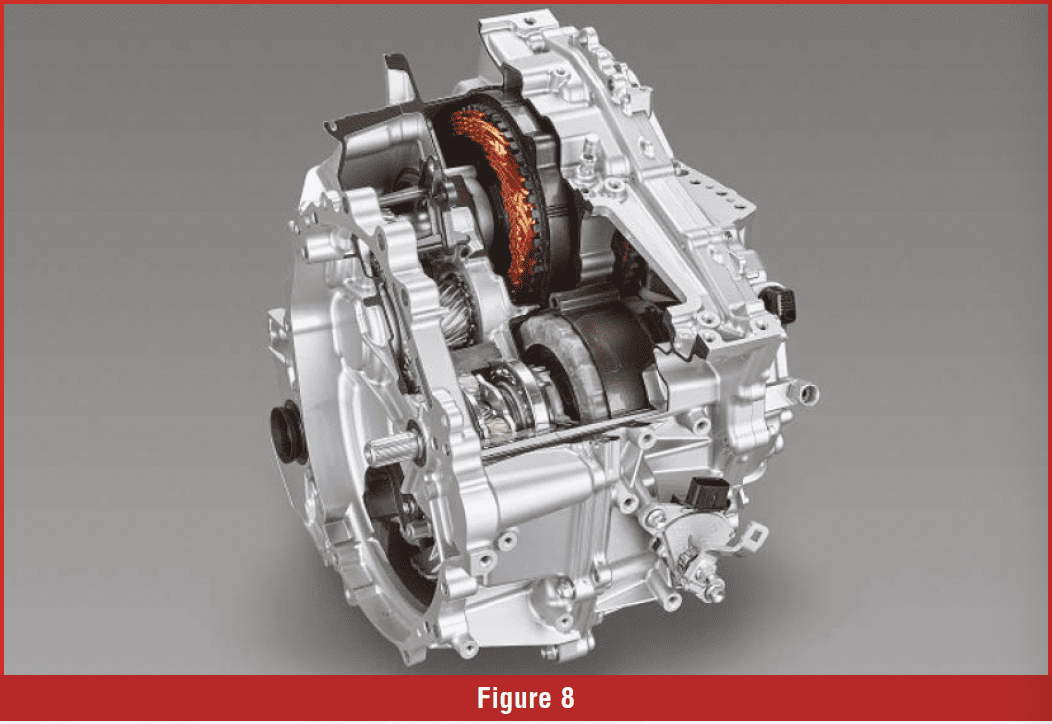

Gen 4 transaxle design retained MG1 & MG2 but eliminated the inline axis in favor of a parallel axis. (Figure 8)  The motor speed rating was increased to 17,000 RPMs. Increasing the motor speed rating allows a faster speed in electric mode. Gen 4 retains the PSD. The total gear ratio of a Gen 4 Prius is 10.838:1, and a Prius Prime has a total gear ratio of 12.3:1. MG2 motor torque has been decreased again to 120 pound-feet of torque. We can determine total torque output in electric mode by multiplying MG2 torque times the total gear ratio. 120 x 10.38 = 1300.46 pound-feet of torque in the regular Prius. The Prius Prime is 120 x 12.3 = 1476 pound-feet of torque. As the generations progressed, MG2 continued to get smaller with less magnetism in the rotor and less torque output; however, the overall torque output has increased with each generation. How were we able to increase torque? We were able to increase torque by changing the total gear ratio. Let’s review all the total gear ratios of each generation.

The motor speed rating was increased to 17,000 RPMs. Increasing the motor speed rating allows a faster speed in electric mode. Gen 4 retains the PSD. The total gear ratio of a Gen 4 Prius is 10.838:1, and a Prius Prime has a total gear ratio of 12.3:1. MG2 motor torque has been decreased again to 120 pound-feet of torque. We can determine total torque output in electric mode by multiplying MG2 torque times the total gear ratio. 120 x 10.38 = 1300.46 pound-feet of torque in the regular Prius. The Prius Prime is 120 x 12.3 = 1476 pound-feet of torque. As the generations progressed, MG2 continued to get smaller with less magnetism in the rotor and less torque output; however, the overall torque output has increased with each generation. How were we able to increase torque? We were able to increase torque by changing the total gear ratio. Let’s review all the total gear ratios of each generation.

- Gen 1-3.89:1

- Gen 2-4.1:1

- Gen 3-8.57:1

- Gen 4-10.838:1

- Gen 4 Prius Prime 12.3:1

This article on Hybrid gear trains and the last article on EV gear trains should help clear up the mystery of why these transaxles have no shifting of gears.

About the Author: Jerry Stewart develops technical training at AVI and teaches automotive technology at Highlands College in Montana. He bridges the gap between industry and academia, equipping students with real-world skills for careers in the transportation field.