The age-old problem of the torque converter clutch killing the engine at a stop in gear seems never to go away. It has been a problem that we’ve been fighting for several decades in different makes and models. But, unfortunately, even on the vehicles we are familiar with, we get bit in a way that we didn’t quite expect.

Here, we will look at one of the icons of the industry for TCC-related issues; the Dodge 47RE transmission. Let’s take a step-by-step approach to accurately identify the source of a TCC-related engine stall condition.

LOOKING AT THE BIG PICTURE

The saying, “You can’t see the forest for the trees,” holds true when we get an old school unit like this into the shop. It turns into a situation of ‘been there and done that.’ So now it’s a matter of going through the motions of doing it yet another time. But, little did you know, this was the unit assigned to eat your lunch!

A 1999 Dodge 2500 with a 5.9L Cummins diesel and a 47RE comes into your shop with a complaint of stalling coming to a stop. The issue is not there when the vehicle is cold, but as the unit warms, it appears as a drag to the engine until you experience the stalling complaint. Depending on our past experiences, several items immediately pop into our minds as the cause. However, before we jump to conclusions, let’s put all possibilities on the table so we can use our best diagnostic tool, the vehicle, as our test bed.

A 1999 Dodge 2500 with a 5.9L Cummins diesel and a 47RE comes into your shop with a complaint of stalling coming to a stop. The issue is not there when the vehicle is cold, but as the unit warms, it appears as a drag to the engine until you experience the stalling complaint. Depending on our past experiences, several items immediately pop into our minds as the cause. However, before we jump to conclusions, let’s put all possibilities on the table so we can use our best diagnostic tool, the vehicle, as our test bed.

Since 47RE doesn’t have a lot of technology attached to it, the list of items to be checked is not long but needs to be addressed with accuracy. Areas to inspect that cause a TCC-related engine stall coming to a stop are as follows:

- Cooler flow

- Electrical

- Valve body

- Pump

- Converter

Using a process of elimination will help us focus on the areas of concern confidently. So, let’s start with the easiest and work our way to the most difficult.

Using a process of elimination will help us focus on the areas of concern confidently. So, let’s start with the easiest and work our way to the most difficult.

If we start with checking the cooler flow, this is the quickest and easiest thing to do; loop the cooler lines. Bypassing the cooling system eliminates a cooler restriction as an issue with one exception. If the cooler return is restricted inside the transmission, this would be the equivalent of a cooler restriction. Blow air into the rear cooler fitting using no more than 40 psi of pressure. The air should enter the unit with minimal resistance.

Another test to perform if you suspect the cooler requires a helper. Remove and place the cooler return line in a bucket. Then, have someone start the vehicle and put it into gear. Not only will you find out if it still stalls the engine, but you’ll see how cooler flow is performing.

CHECK THE ELECTRICAL SIDE

CHECK THE ELECTRICAL SIDE

If the cooler flow is good and the stalling issue is yet present, check the electrical signal to the TCC Solenoid. We can unplug the transmission connector on this unit and test it for stalling. We are killing power and ground control to the unit without affecting line pressure.

Note that this test can be misleading on many transmissions with a pressure control solenoid. When you unplug the transmission on typical electronic pressure control systems, line pressure goes to maximum, with a higher converter release pressure. The higher pressure can mask the problem and lead you to an incorrect diagnosis of an electrical issue. Since the 47RE has a governor pressure solenoid instead of a line pressure control solenoid, this is a good test.

INSIDE THE VALVE BODY

INSIDE THE VALVE BODY

If the problem persists, it’s time to look inside the valve body. These valve bodies have been around for over 20 years and have had problems, even on the best days of their lives.

One area of concern is the switch valve. The circuit timing of the TCC operation is critical. Timing issues can cause symptoms like soft TCC apply, shudder complaints, and increased damper spring loads. Always inspect the valve bore for excessive wear, valve damage, and proper valve operation (figure 1).

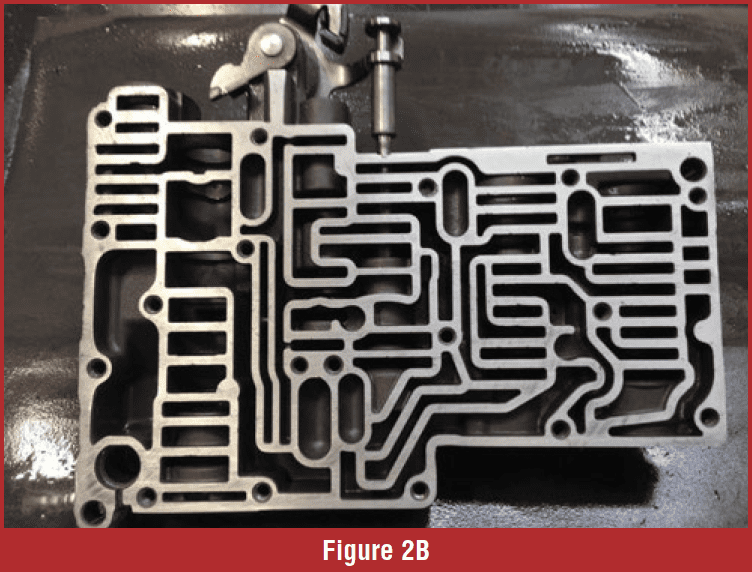

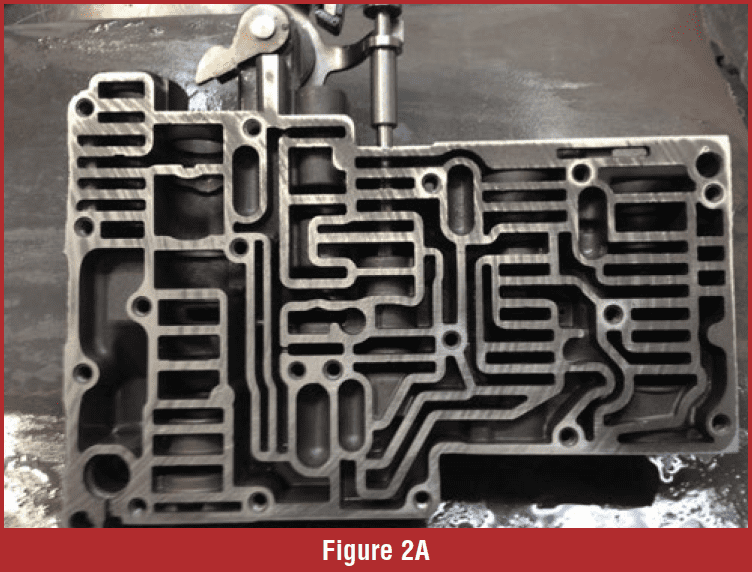

These valve bodies can always use extra tender loving care. Warpage from years of service is expected (figures 2A and 2B). The warpage causes pressure losses and control-oil leaks. Flat sanding is necessary to restore the hydraulic integrity of the valve body as best as possible.

To check the valve body for flatness, use a piece of glass and a sheet of 220 wet/dry sandpaper. Wet the sandpaper with a mix of liquid dish soap and water, then sand each machined surface of the valve body.

BEYOND THE VALVE BODY

BEYOND THE VALVE BODY

If the stalling issue is still present after addressing cooler flow and electrical and valve body concerns, we must suspect the problem is in the pump or torque converter. However, here’s where creativity could be your friend. Since we can get to the valve body, we can modify it to ensure that lock-up cannot hydraulically occur through valve movement.

If we block the Converter Clutch valve, Converter Clutch Timing valve, and the Switching valves in their resting position (figure 3), oil would have to take a different path to apply the TCC. We would need to pull the transmission for a closer look.

In this case, we ended up with the same problem. However, we observed this problem would only happen after the front clutch was applied. The valve body was removed, and an air check of the front clutch showed air coming out of both torque converter passages (figure 4). We verified that the unit needed to be removed to fix the problem.

INSPECTING THE PUMP

The transmission was removed for a closer inspection. The front and rear clutch were placed on the assembled pump on the bench for air test purposes. When we supplied air to the front clutch, we observed air exiting the torque converter in and out passages. For comparison, the same air test was conducted using a different pump and showed no air coming from the torque converter in and out passages when we applied air to the front clutch passage.

We disassembled the pump for a closer look (figure 5). We checked the stator support for warpage using a flat file and found issues immediately. Use compression film or Plasti-gauge to determine if the warpage occurred accurately. The stator support in question was warped in the area of the feed holes, causing the cross leak.

Good used pumps are getting harder to find nowadays. Several shops can machine the surfaces in-house or have a machine shop that will do this for them. Remember to check the stator support for warpage before unit assembly.

THE TORQUE CONVERTER

The last thing on the list is the torque converter. It is the least likely thing to cause the problem, but it can. For example, if an aftermarket multiple-disc converter clutch is installed, then TCC apply, and release is more aggressive by design. If the valve body is compromised, installing a multiple disc torque converter can magnify the concerns and cause a stalling condition. After exhausting all the previous possibilities, replace the torque converter.

Slowing down to take a broad look at common problems can save time and unnecessary heartaches. And that’s not just smart; that’s street smart!