In this issue of Keep Those Trannys Rolling, we are going to take a look at a 2017 GMC Acadia that was experiencing a harsh/delayed engagement during auto stop/start events. According to the customer, he was experiencing a harsh/delayed engagement during auto stop/start events. If he disabled the auto stop/start function, the transmission seemed to work fine. The customer said that he had a scanner and that he had scanned the computer system and found code P171D (accumulator performance) stored in the Transmission Control Module (TCM). The customer said that he had googled the DTC and found several listings related to transmission accumulator concerns. The customer went on to say that they had ordered an accumulator assembly from EBAY and had a local repair shop install it for them. Unfortunately, the harsh/delayed engagement concern continued, and code P171D reset in the TCM (Transmission Control Module).

Initial Inspection

After giving the customer a ride home, we started off by performing our initial vehicle inspection. This vehicle was equipped with a 2.5L engine and a 6T50 transmission. As usual, we started our initial inspection with a “walk-around” inspection. During the inspection, we noticed numerous scratches and a couple of minor dents on the vehicle. The scratches and dents were documented, and we continued our initial inspection with an under-hood inspection, checking hoses, belts, harnesses, and fluid levels. During the under-hood inspection, we noticed several engine harness clips were damaged, and the hoses and belts had recently been replaced. It was obvious that someone had been working under the hood. Other than that, everything looked good. We raised the vehicle up on the rack to inspect the underside of the vehicle. We checked the engine, transmission, differential, and suspension. Again, everything looked good. With the initial inspection completed, it was time to head out on our test drive to see if we could duplicate the customer’s delayed/harsh engagement concern during a stop/start event.

Duplicate to Diagnose

In preparation for our test drive, we connected our scan tool to the vehicle’s Data Link Connector (DLC) and checked each individual module for codes. We found code P171D stored in the TCM (Transmission Control Module), but no other codes were found in any other module. We documented the code and cleared it from the TCM. With all computer systems cleared of codes, we headed out for our initial test drive.

Initial Test Drive:

With the scan tool connected to the DLC and codes cleared from all computer systems, we headed out for our test drive. During the test drive, we drove through residential areas and city streets. We drove in light, heavy, and stop-and-go traffic. During auto stop/start events, we noticed that when the engine restarted, the transmission felt like it had fallen out of gear and then harshly re-engaged. When we disabled the auto stop/start function, the transmission seemed to work properly. This was an indication that we were having an auto stop/start system concern. After completing our test drive and duplicating the customer’s concern, it was time to head back to the shop for further diagnosis.

Back at The Shop

With the vehicle back at the shop, we checked each of the computer systems for codes. Again, we found code P171D reset in the TCM. There were no codes set in any other modules. It was time to take a look at the diagnostic routine and possible causes for code P171D.

G.M.’s Diagnostic Routine for Code P171D

As per G.M., the diagnostic routine for code P171D is pretty straightforward.

- Engine idling, transmission in Park, with parking brake applied and drive wheels chocked.

- Verify the transmission fluid level and condition is correct.

- Clear the ECM and TCM DTCs with a scan tool.

- If DTC P171D resets, replace the Transmission Fluid Pressure Accumulator.

With the transmission accumulator replaced, it was time to take another look at what triggers a code P171D.

Understanding Code P171D

The TCM uses the input speed sensor (ISS) to monitor clutch slip during an auto start event. Code P171D will set if the TCM detects that the accumulator system is not capable of supplying adequate pressure to the transmission during seven (7) consecutive auto start events.

Purpose of the Accumulator:

When the engine is shut off during an auto stop event, there is no transmission line pressure. The automatic transmission auxiliary fluid accumulator’s purpose is to provide line pressure to the transmission during an auto start event. The accumulator is externally mounted to the transmission case assembly. The ECM (Engine Control Module) controls the automatic transmission auxiliary fluid accumulator solenoid valve by providing a ground path to the solenoid valve control circuit. During an auto start event, the ECM commands the automatic transmission auxiliary fluid accumulator solenoid valve on, allowing transmission fluid to discharge from the accumulator, supplying line pressure to the transmission. Now that we have a better understanding of how the automatic transmission auxiliary fluid accumulator system operates, let’s take a look at the actual diagnostic routine we used to correct code P171D on vehicle.

Diagnosing Code P171D

Having a better understanding of how the fluid accumulator system works, we started our diagnostic routine by installing a pressure gauge on the line pressure tap to monitor line pressure and a scanner to the DLC to monitor the TCM and ECM while driving. We headed out for another test drive to monitor line pressure during auto stop/start events. Again, we drove through residential areas and city streets. We drove in light, heavy, and stop-and-go traffic. During our test drive, we noticed that the line pressure would drop to zero (0) psi during auto stop events and rise to sixty (60) psi during auto start events. It appeared that the auto stop/start system was working as designed. We monitored the transmission solenoid operation during auto stop/start events and found the solenoids were being commanded on and off as they were supposed to be. Apparently, we were having an internal transmission problem and needed to further diagnose this delayed/harsh engagement concern.

Diagnosing a Delayed/Harsh Engagement Concern

With the pressure control system and solenoid operating properly, we suspected an internal transmission problem. With the customer’s permission, we removed the TECHM-valve body assembly from the transmission for inspection. We vacuum checked the valve body, expecting to find valve body wear. To our surprise, the valve body was in good shape. We did a visual inspection of the TECHM, and it seemed to be okay. We air checked our clutch components with thirty-five (35) psi of regulated air pressure. During the air check, we found the 1234 clutch had excessive leakage. We contacted the customer to inform him that he had an internal problem in the 1234 clutch circuit, and further inspection was needed. With the customer’s approval, we removed the transmission and disassembled it for inspection.

Problem Found:

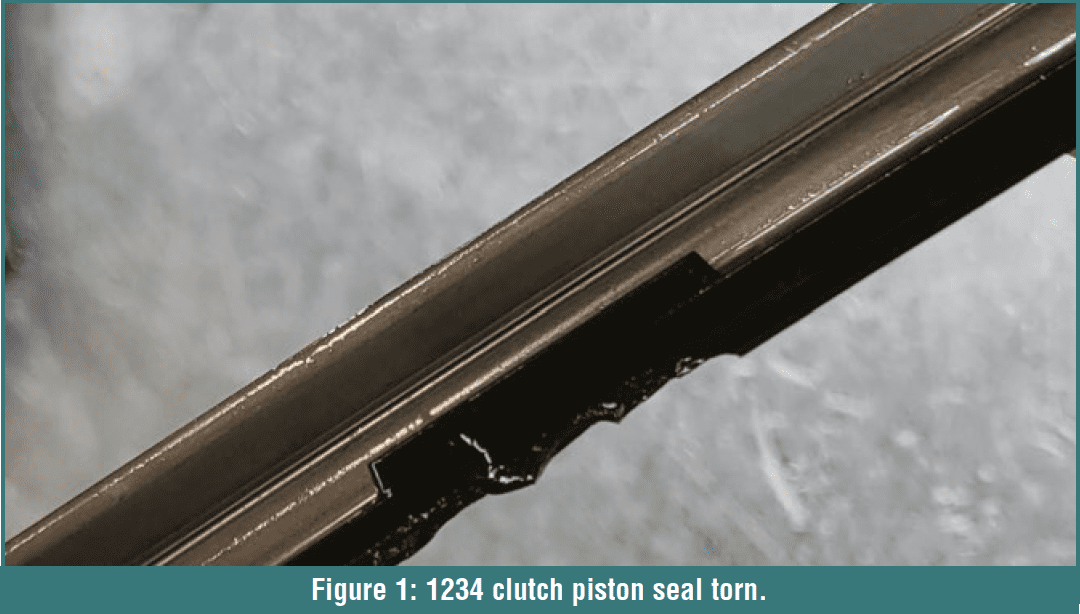

With the transmission disassembled on the bench, we inspected the 1234 clutch circuit. We checked the sealing rings and grooves for wear. We checked the 1234 clutch drum for any signs of cracks; there were none. We disassembled the 1234 clutch drum and found that the 1234 clutches were slightly burnt, and the piston seal was torn (Figure 1).  We recommended overhauling the transmission due to mileage. We overhauled the transmission and installed it in the vehicle. After the installation, we test drove the vehicle several times, and the transmission seems to be working perfectly. We delivered the vehicle to the customer a couple of weeks ago, and he says the transmission has been working perfectly.

We recommended overhauling the transmission due to mileage. We overhauled the transmission and installed it in the vehicle. After the installation, we test drove the vehicle several times, and the transmission seems to be working perfectly. We delivered the vehicle to the customer a couple of weeks ago, and he says the transmission has been working perfectly.

Well, there you have it. With a better understanding of how the 6T Auto Start/Stop system operates, you too can keep those trannys rolling down the road.