Most transmission shops are now starting to work on CVTs. At first, most techs were kind of scared of the new design transmission and thought it was unreliable. Many builders said that the CVT wouldn’t last long on the market.

But CVTs aren’t going away soon, so let’s prepare for the change and start building these profitable units.

Another excuse we hear for not building Jatco CVTs is that you can’t buy parts. Let’s clear up the parts issue: Some parts are still hard to find but, for the most part, transmission distributors are now stocking most parts needed. Some of the bearings are still hard to get, but if your local transmission parts warehouse doesn’t have them, you can find most of them online.

After reading this article, you’ll have a basic understanding of what needs to be done when a Nissan CVT comes into your shop. The most important part of working on CVTs is the initial checkout. This can be the difference between making good money and losing money, so let’s talk about how to do it right.

ELECTRICAL

Let’s start with the basics: static battery charge voltage and charging system voltage.

The first thing to do is open the hood and check the battery voltage before you even start the engine. The battery voltage with the engine off should be around 12.6 volts. This is the measurement straight across the battery posts.

Once you start the engine, charging system and battery voltage should be around 14.0 volts.

We’ve seen many vehicles come into the shop with solenoid codes and engine performance issues with low battery voltage. The vehicle started just fine and you couldn’t tell the battery had low voltage unless you measured it with a meter.

Now to check some basic grounds: Connect the negative lead of the meter to the negative side of the battery, and the positive lead to the engine ground. With the engine running, you should have less than 0.1 volts.

Now move the lead from the engine and test the transmission case; you should have the same reading. Then move the lead from the transmission to the body ground. The engine, transmission and body should all have less than 0.1 volts. If one’s higher than the other, you need to inspect the wire and mounting condition.

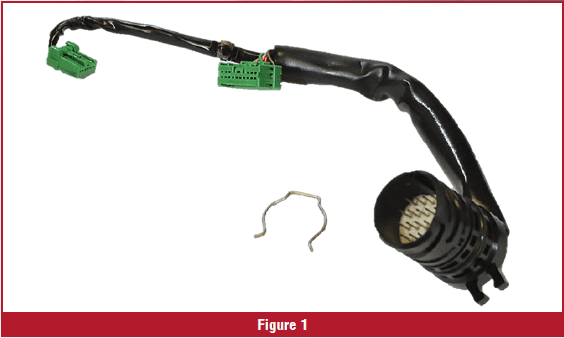

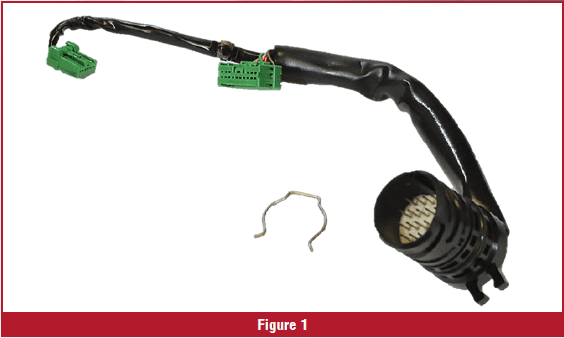

We’ve also seen many electrical issues caused by corrosion and broken pins in the case connector. The pins in the case connector are very small; be careful when plugging or unplugging the case (figure 1).

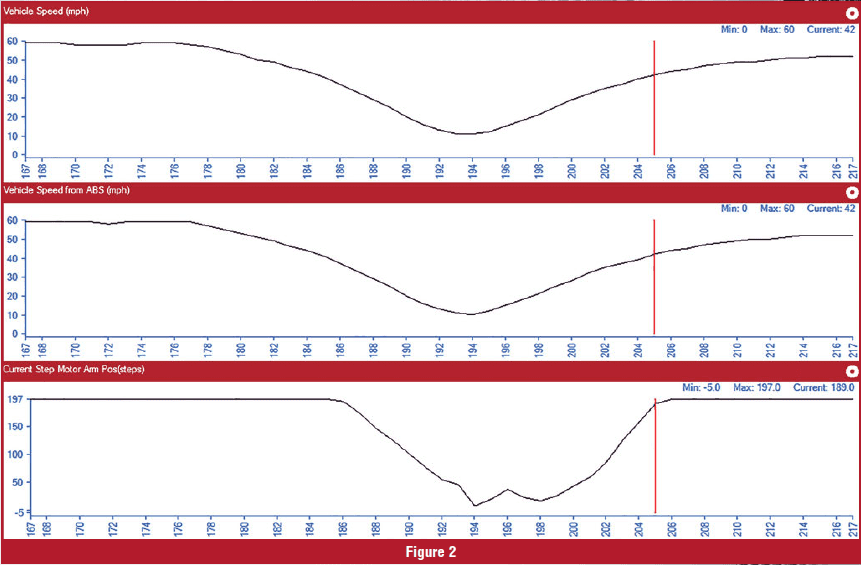

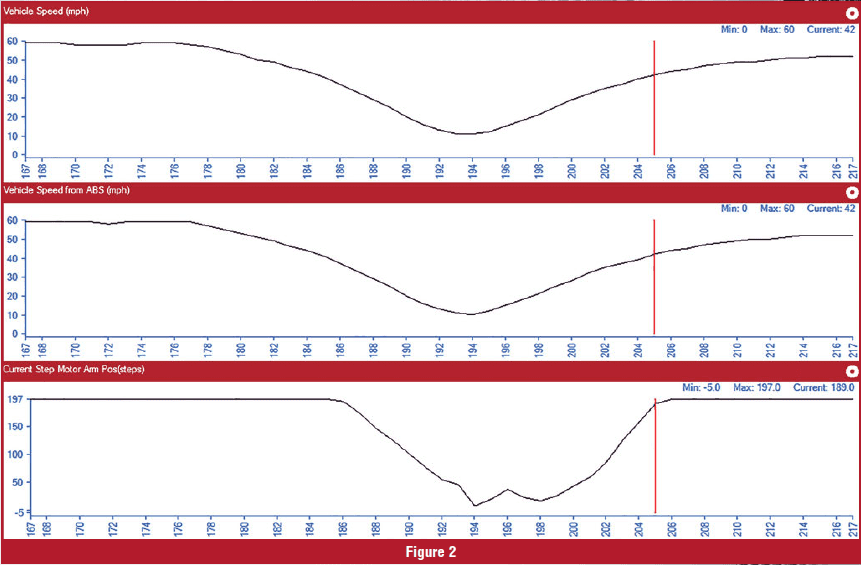

Get used to looking at scan data and PID information. Whenever you get a chance to save and record good data, make the time to do it. If the complaint is that the ratio won’t change, graph out vehicle speed, vehicle speed from ABS, and current step motor arm position (figure 2).

Examine these PIDs first to make sure the transmission controller is seeing the same speed signal from the transmission and the ABS system.

The current stepper motor arm position PID tells you if the computer is changing ratio. A low number of steps from takeoff is normal. The steps should rise as speed increases.

ABS AND TRACTION CONTROL SYSTEM

One thing that’s often overlooked on CVTs is the ABS and traction control system. Always get into the ABS wheel speed sensors in the ABS section of the scan tool. You’ll want to graph out all four wheel speed sensors while driving straight and make sure they all read the same.

Many times, you’ll have a dirty reluctor wheel and that’s all it takes to cause transmission issues. Wheel speed sensor codes may not appear, but they still have problems.

Wheel speed sensor issues can cause engine performance and ratio change problems. The computer system doesn’t want you to spin the tires, so it controls ratio change and drop off of engine loads with no codes.

Some other sensors to look at are the yaw rate sensor, sometimes called the G sensor, and the steering angle sensor. After you’ve installed the transmission, you’ll want to relearn the steering wheel and yaw sensors. You can usually do this with your scan tool set to functional test.

MAIN TRANSMISSION ISSUES

Most Nissan CVTs have a ROM that stores transmission relearn information. This ROM is a small, black box that mounts next to the valve body (figure 3). You can swap the ROM from one transmission to another to avoid reinitialization. Some scan tools are able to do the re- initialization now, so you don’t have to send the car to the dealer.

Keep in mind, if you buy a transmission, some manufacturers don’t want you to swap the ROM and want you to reprogram. It’s always best to have the latest programming in any transmission.

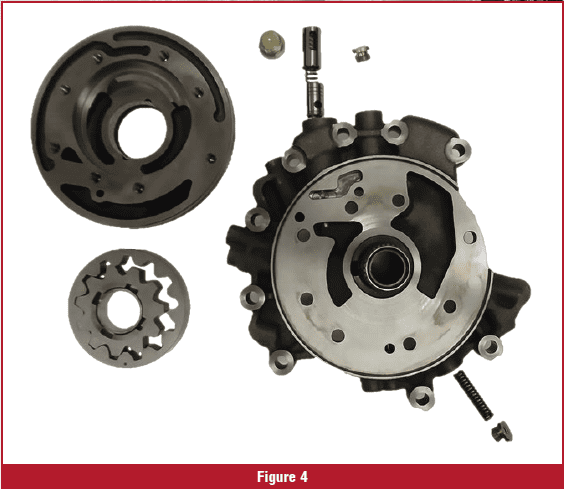

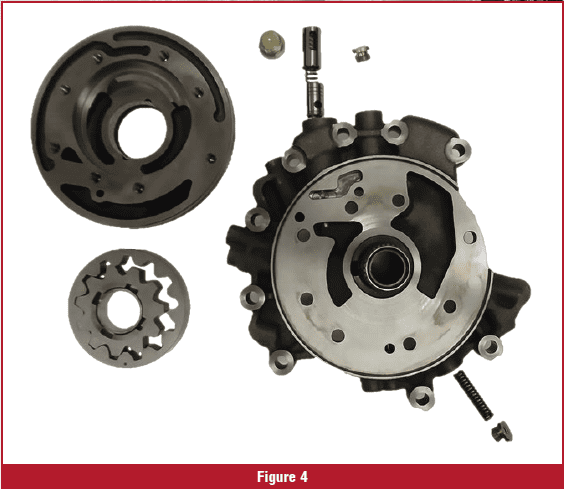

Some of the main problems seen in these transmissions are worn or stuck flow control valves (figure 4). The flow control valve controls the oil volume to the transmission.

Some of the codes you’ll get from a stuck or worn flow control valve are secondary pressure codes. There are aftermarket repairs from Sonnax and Transgo. Some of the repairs are dropin components; others will need tools.

You’ll need to disassemble the pulleys on every rebuild. Fine metal and debris likes to find its way behind the seal in the pulleys. This will cause a large leak and belt slip.

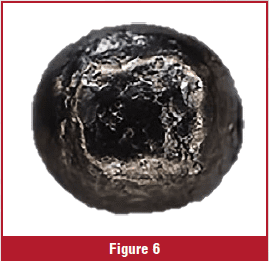

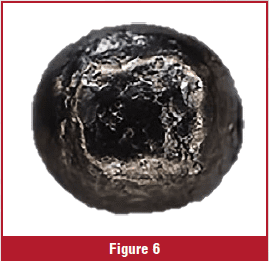

Other areas to inspect inside the pulleys are the balls and grooves they ride in (figure 5). There are three grooves on each side of pulley to inspect. The pulley sleeves need to slide up and down smoothly and freely when put together.

If you find the balls broken up or rough (figure 6), there are aftermarket balls available. Seal Aftermarket Products has designed a roller to replace the balls; the roller comes in their overhaul kit. These rollers can also save a worn pulley if it isn’t too bad.

If the pulleys have some metal buildup, most times you can clean them up with sandpaper. Always replace the chain when this happens. Make sure you check all the bearings on the pulleys and differentials. Bearing pitting causing noise is a common complaint.

You’ll want to disassemble the valve body completely, with each valve taken out of the bore and inspected. CVTs produce a fine material that easily hangs valves. We’ve fixed many valve bodies by taking the valves completely out and cleaning the bore. Don’t just pick the valves because that doesn’t work in this transmission.

For the most part, solenoids and switches have been fairly reliable. There are now some aftermarket solenoids available for the CVT if needed. Other times you’ll have to buy a complete valve body.

To sum up, when you get a CVT in the shop, start by performing thorough voltage checks. Go to the ABS section and check the operation of the wheel speed sensors.

When you have the transmission out, inspect the flow control valve and the disassembled pulleys. Don’t forget to inspect the bearings and the rollers on the pulleys.

Never shortcut the valve body by picking the valves. Take the time to clean each valve.

If you take these extra steps while working on a CVT, you’ll soon enjoy the extra income from working on CVTs.